Table of Contents

Powering the Heart of Heavy-Duty Trucks

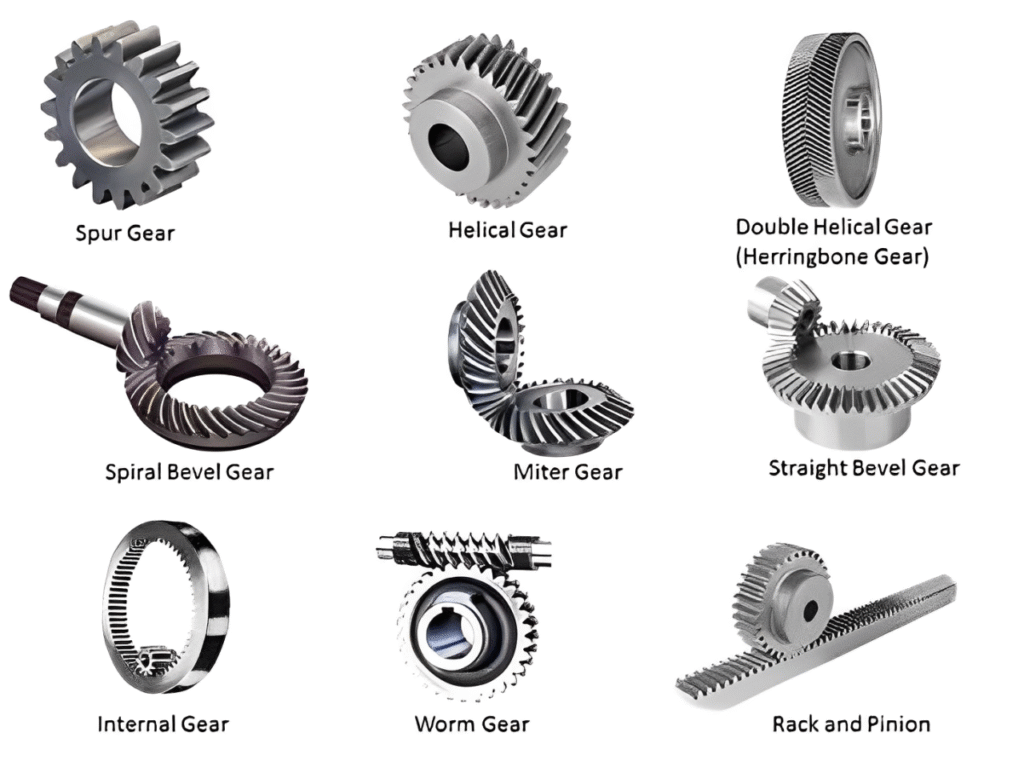

Truck transmissions are the unsung heroes of heavy-duty vehicles, transforming raw engine power into the force that drives the wheels. At the core of these systems are bevel gears, which redirect torque and rotation, often at a 90-degree angle, to keep trucks moving smoothly under demanding conditions. Among bevel gears, spiral bevel gears stand out as the superior choice for modern trucks, outperforming straight bevel gears in efficiency, durability, and driver comfort. In this comprehensive guide, we’ll dive into why spiral bevel gears are the go-to option for truck transmissions, exploring their design, real-world applications, and unique advantages, including their close cousin, the hypoid Gear. Whether you’re a fleet operator, truck manufacturer, or simply curious about transmission technology, this blog will explain why spiral bevel gears are revolutionizing trucking.

The Role of Bevel Gears in Truck Transmissions

Bevel gears are essential for redirecting rotational force in truck drivetrains, particularly in differentials and transfer cases. Imagine them as the handshake between two shafts meeting at an angle, ensuring power flows smoothly to navigate turns or haul heavy loads. Spiral bevel gears, with their curved, angled teeth, differ significantly from straight bevel gears, which have linear teeth. This unique design—akin to a gentle, rolling handshake rather than a sharp high-five—offers a range of benefits that make spiral bevel gears ideal for the rugged demands of trucking, from urban deliveries to long-haul freight.

Key Features of Spiral Bevel Gears

Spiral bevel gears are engineered for performance, combining advanced tooth design with practical benefits. Here’s what sets them apart:

- Curved Tooth Design for Smooth Engagement

Unlike straight bevel gears, which have straight teeth that clash abruptly, spiral bevel gears feature curved, helical teeth that engage gradually, much like gears meshing in a smooth, rolling motion. This results in a contact ratio of 2.2 to 2.9, meaning 2–3 teeth share the load at any moment, reducing stress on individual teeth. Picture a team of workers passing a heavy load hand-to-hand instead of one person carrying it alone—this teamwork makes spiral bevel gears stronger and more resilient

- Whisper-Quiet Operation

The helical tooth pattern minimizes vibration and noise, making spiral bevel gears significantly quieter than straight bevel or spur gears. For truck drivers, this means a quieter cab, reducing fatigue on long hauls. Tests show spiral bevel gears produce 10–15% lower decibel levels than straight bevel gears at highway speeds, creating a more comfortable driving environment.

- High-Efficiency Power Transfer

By spreading the load across multiple teeth, spiral bevel gears reduce friction and heat, achieving mechanical efficiencies of 96–99%. This means nearly all engine power reaches the wheels, unlike straight bevel gears, which lose 5–10% more energy to friction. For fleet operators, this efficiency translates to fuel savings, a critical factor in today’s cost-conscious trucking industry.

Spiral Bevel Gears vs. Straight Bevel Gears: A Head-to-Head Comparison

Performance Under High Loads

Trucks face diverse challenges, from hauling heavy cargo on highways to navigating rugged off-road terrain. Spiral bevel gears excel in both light-duty and heavy-duty scenarios due to their ability to handle high torque and axial loads. Their rolling tooth engagement ensures smooth power transfer, even under extreme stress, making them ideal for trucks like the Volvo FH16 or Daimler Freightliner Cascadia used in long-haul transport.

Durability for the Long Haul

The gradual meshing of spiral bevel gears reduces wear and tear, extending Gear life by up to 50% compared to straight bevel gears in heavy-duty applications. Straight bevel gears, with their abrupt tooth contact, are prone to impact damage, especially when towing or climbing steep grades. For example, in off-road logging trucks, spiral bevel gears withstand constant torque spikes better, reducing the risk of premature failure.

Reduced Noise and Vibration

Noise and vibration affect driver comfort and component longevity. Spiral bevel gears’ smooth engagement minimizes shock loads, producing less noise and vibration than straight bevel gears, especially at speeds above 50 mph. This is a game-changer for long-haul drivers, as a quieter cab reduces fatigue and improves focus, enhancing safety on the road.

Hypoid Gears: The Spiral Bevel Variant

A close relative of spiral bevel gears, hypoid gears are widely used in truck differentials, particularly in rear-wheel-drive models like the PACCAR MX-13-powered Kenworth T680. Hypoid gears have an offset axis, allowing a larger pinion diameter that improves heat dissipation and torque capacity. While their efficiency (90–95%) is slightly lower than standard spiral bevel gears due to increased sliding, they excel in heavy-duty applications. However, hypoid gears require specialized high-pressure lubricants to manage sliding friction, adding a layer of maintenance complexity but ensuring robust performance in demanding conditions.

Efficiency and Maintenance: Saving Time and Money

Superior Load Distribution

The ability to distribute loads across multiple teeth enhances the strength and durability of spiral bevel gears. The face load factor (KHβ), typically 1.5–1.7, indicates efficient load spreading, reducing localized wear and tooth fractures. This is like distributing weight across multiple beams in a bridge, ensuring no single point bears too much stress.

Maintenance Best Practices

For optimal performance, spiral bevel gears should be replaced in matched sets, as manufacturers precision-lap them for a perfect fit. This ensures consistent meshing and minimizes wear. While spiral bevel gears can handle brief torque spikes, repeated overloading can shorten gearbox and bearing life. Regular maintenance, including proper lubrication and precise shimming, is critical to maximizing their 100,000+ mile service intervals—double the 50,000–70,000 miles typical for straight bevel gears.

Long-Term Cost Savings

Spiral bevel gears have a higher upfront cost due to their complex manufacturing, often 20–50% more than straight bevel gears. However, their extended lifespan and reduced maintenance needs make them cost-effective over time. Fleet operators report up to 30% lower maintenance costs and less downtime, translating to thousands of dollars in savings over a truck’s life.

Challenges and Limitations

While spiral bevel gears offer significant advantages, they’re not without challenges:

Higher Initial Cost: Their intricate design requires advanced machining, increasing production costs. For smaller fleets, this upfront investment can be a hurdle, though long-term savings offset it.

Specialized Maintenance: Precise installation with high-quality Bearings and shimming is essential. Improper setup can lead to noise or premature wear. Hypoid gears, in particular, require specialized lubricants, adding to maintenance complexity.

Overload Sensitivity: While robust, spiral bevel gears can suffer reduced lifespan if consistently overloaded beyond their rated torque, emphasizing the need for proper gearbox sizing.

Addressing these challenges through proper design and maintenance ensures spiral bevel gears deliver their full potential.

Real-World Applications: From Trucks to Beyond

Spiral bevel gears are a cornerstone of truck differentials, powering models like the Volvo FH16 for long-haul routes or the Ram 3500 for heavy-duty towing. Their ability to transfer torque quietly and efficiently is critical in these applications. For example, in off-road conditions, spiral bevel gears in a Ford F-550 Super Duty handle the stress of uneven terrain better than straight bevel gears, reducing wear on the drivetrain.

Beyond trucking, spiral bevel gears are used in:

Aerospace: Helicopter transmissions rely on their compact, high-torque design.

Wind Energy: Wind turbine gearboxes use spiral bevel gears for efficient power transfer.

Material Handling: Forklifts and conveyor systems benefit from their quiet operation.

Remote-Controlled Vehicles: Enthusiasts note smoother, quieter performance in high-performance RC trucks.

These diverse applications highlight the versatility and reliability of spiral bevel gears across industries.

Technical Insights: Load Distribution and Contact Stress

The performance of spiral bevel gears hinges on their ability to manage load distribution and contact stress. The face load factor (KHβ = 1.5–1.7) ensures loads are spread evenly across the gear teeth, reducing the risk of localized wear. The bevel gear factor (ZK = 0.85, per ISO 10300:2014 standards) allows spiral bevel gears to handle contact stress effectively, preventing cracks or deformation under heavy loads. These metrics, derived from Loaded Tooth Contact Analysis (LTCA), confirm why spiral bevel gears are built for durability.

Visual Aid Suggestion: A diagram showing the curved tooth engagement of spiral bevel gears vs. the abrupt contact of straight bevel gears would clarify this concept. Imagine a side-by-side comparison with arrows indicating load distribution across multiple teeth for spiral gears, contrasted with a single-tooth load for straight gears.

Why Spiral Bevel Gears Are the Future of Truck Transmissions

As trucks evolve to meet stricter fuel efficiency and emissions standards, spiral bevel gears are increasingly vital. Their high efficiency (96–99%) reduces fuel consumption, while their compact design allows manufacturers to build smaller, lighter gearboxes without sacrificing torque capacity. This is critical for next-generation trucks like the Tesla Semi, which prioritize efficiency and space optimization. Additionally, their quiet operation aligns with growing demands for driver comfort and safety.

Industry Data and Performance Metrics

Efficiency: Spiral bevel gears achieve 96–99% efficiency, vs. 90–95% for straight bevel gears.

Service Life: Up to 50% longer in heavy-duty applications, often exceeding 500,000 miles.

Maintenance Intervals: 100,000+ miles vs. 50,000–70,000 miles for straight bevel gears.

Noise Reduction: 10–15% lower decibel levels, improving driver comfort.

Fuel Savings: Up to 5% better fuel economy due to reduced energy loss.

FAQs

Q: Why are spiral bevel gears more expensive?

Their curved tooth design requires advanced machining and precision lapping, increasing production costs. However, their longer lifespan and lower maintenance costs offset the initial investment.

Q: Can spiral bevel gears be retrofitted into older trucks?

Yes, but it requires compatible gearbox designs and precise installation. Consult a transmission specialist to ensure proper fitment.

Q: How do hypoid gears differ from spiral bevel gears?

Hypoid gears have an offset axis, allowing higher torque in compact designs but requiring specialized lubricants. They’re common in truck differentials for heavy-duty applications.

Q: What maintenance do spiral bevel gears require?

Regular lubrication with high-quality gear oil, precise shimming, and periodic inspections ensure optimal performance and longevity.

Conclusion: The Gold Standard for Truck Transmissions

Spiral bevel gears are the ultimate choice for truck transmissions, offering unmatched efficiency, durability, and driver comfort. Their ability to handle high torque, reduce noise and vibration, and minimize maintenance costs makes them ideal for the demanding world of trucking, from long-haul fleets to off-road workhorses. While their higher initial cost and maintenance requirements present challenges, proper installation and care unlock their full potential, delivering significant savings over time. For fleet operators seeking reliability, manufacturers designing cutting-edge trucks, or drivers prioritizing a quiet ride, spiral bevel gears set the standard for performance and value. Invest in spiral bevel gears, and you’re investing in smoother, stronger, and more efficient truck transmissions for years to come.