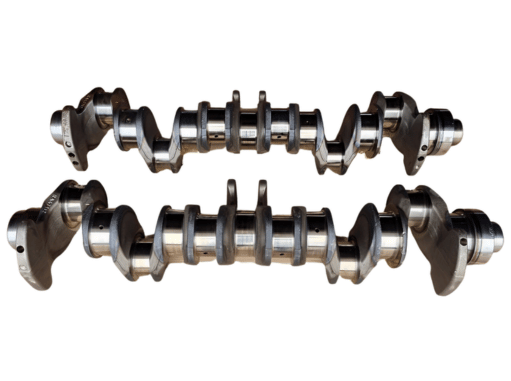

The Mercedes-Benz OM471 crankshaft(4710300401) is a cornerstone of high-performance diesel engines, powering Euro-6-compliant trucks across Germany’s robust logistics and transportation industry. Renowned for its exceptional strength, durability, and precision engineering, the OM471 crankshaft is designed to meet the rigorous demands of long-haul trucking, ensuring reliability and efficiency under the strictest environmental standards. For fleet operators, truck manufacturers, and maintenance professionals in Germany, choosing the right crankshaft is critical to maintaining operational excellence. This is where Volgen Power steps in, offering OEM-quality OM471 crankshafts with fast delivery and unparalleled support.

In this comprehensive guide, we’ll explore why the Mercedes-Benz OM471 crankshaft (4710300101) is the ideal choice for Euro-6 trucks in Germany, delving into its technical specifications, benefits for long-haul transportation, and alignment with Euro-6 emission standards. We’ll also highlight Volgen Power’s role as a trusted supplier, providing high-quality crankshafts tailored to the needs of the German trucking industry. Whether you’re upgrading your fleet or replacing a worn-out component, this article will help you understand why the OM471 crankshaft stands out and how Volgen Power ensures seamless supply.

Table of Contents

Why Euro-6 Compliance Matters in Germany

Germany is at the forefront of environmental regulations in Europe, with Euro-6 standards setting strict limits on nitrogen oxide (NOx) and particulate matter (PM) emissions for heavy-duty vehicles. Introduced in 2014, Euro-6 regulations require trucks to incorporate advanced technologies like selective catalytic reduction (SCR) and diesel particulate filters (DPF) to reduce environmental impact. The Mercedes-Benz OM471 engine, with its integrated crankshaft, is designed to meet these standards, delivering high performance while minimizing emissions.

For German fleet operators, Euro-6 compliance is non-negotiable. Cities like Berlin, Munich, and Hamburg enforce low-emission zones, restricting access to non-compliant vehicles. The OM471 crankshaft plays a pivotal role in ensuring the engine operates efficiently, reducing fuel consumption and emissions while maintaining power output. This makes it an ideal choice for long-haul trucks navigating Germany’s autobahns and urban centers.

According to a 2024 report by the German Federal Motor Transport Authority, over 70% of new heavy-duty trucks registered in Germany are Euro-6 compliant, reflecting the market’s shift toward sustainable transport solutions. By choosing the OM471 crankshaft, fleet operators can ensure their vehicles meet these standards, avoiding fines and gaining access to restricted zones. Volgen Power’s OM471 crankshafts are manufactured to OEM specifications, guaranteeing compatibility with Euro-6 engines and seamless integration into your fleet.

Technical Advantages of the OM471 Crankshaft

The OM471 crankshaft is engineered to deliver exceptional performance in the demanding conditions of long-haul trucking. Below, we explore its key technical advantages:

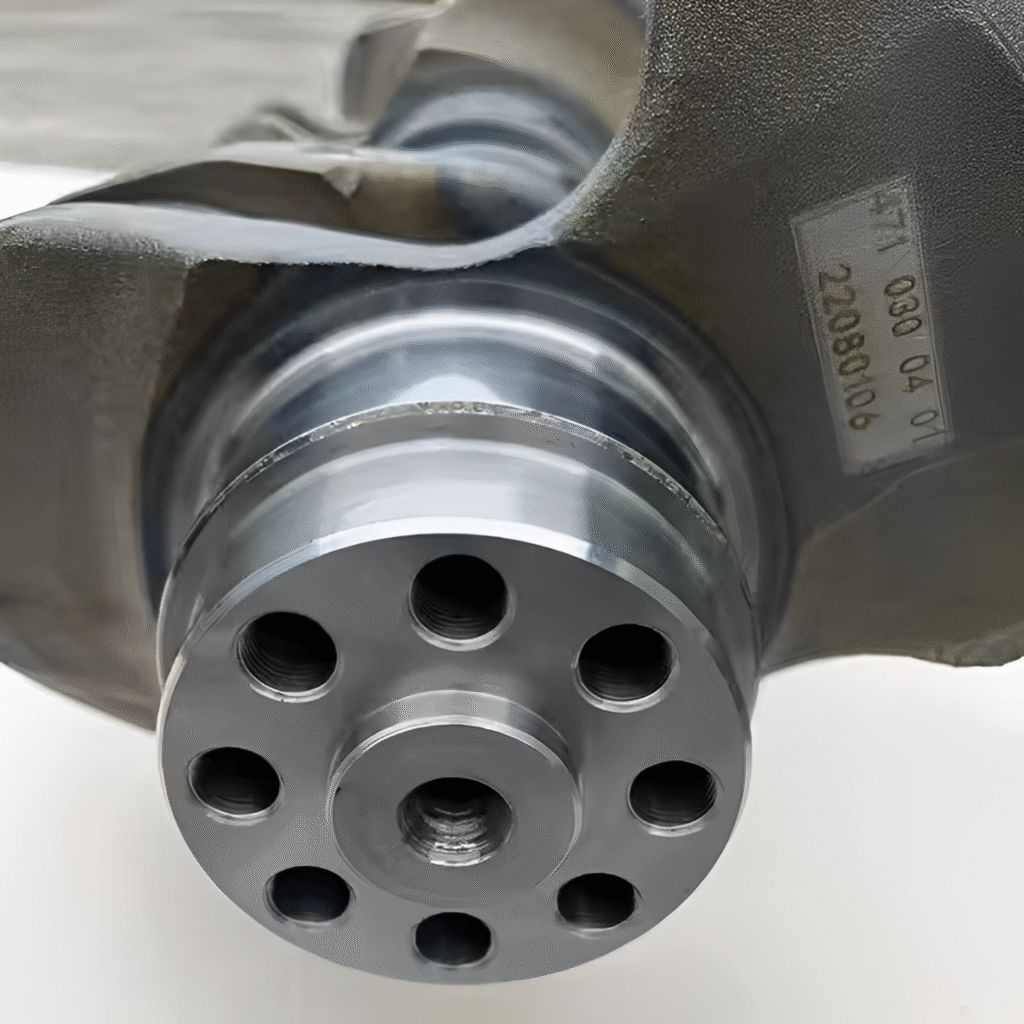

High-Strength Materials and Precision Engineering

OM471 crankshaft is crafted from high-grade forged steel, designed to withstand the intense forces generated by the 12.8-liter engine’s 510 horsepower and 2,500 Nm of torque. Its robust construction ensures resistance to fatigue, cracking, and wear, even under continuous high-load operation. Precision machining guarantees tight tolerances, minimizing vibration and ensuring smooth power delivery.

Optimized Design for Fuel Efficiency

Fuel efficiency is a top priority for German fleet operators, given the high cost of diesel and the need to reduce operating expenses. The OM471 crankshaft’s balanced design reduces frictional losses, optimizing engine efficiency. Combined with the OM471 engine’s advanced common-rail injection system, the crankshaft helps achieve up to 5% better fuel economy compared to previous models, according to Mercedes-Benz data.

Durability for Long-Haul Performance

Long-haul trucks in Germany often cover thousands of kilometers weekly, putting significant stress on engine components. The OM471 crankshaft is built for durability, with reinforced journals and counterweights that enhance stability at high RPMs. Its ability to handle extended operations without deformation makes it a reliable choice for demanding routes, such as cross-country deliveries from Hamburg to Munich.

Volgen Power’s OM471 crankshafts are sourced from trusted manufacturers, adhering to Mercedes-Benz’s stringent quality standards. This ensures that every crankshaft delivers the performance and longevity that German operators expect.

Applications in German Long-Haul Trucks

The OM471 crankshaft is a perfect match for Germany’s long-haul trucking industry, where reliability, efficiency, and compliance are paramount. Below, we explore its key applications:

Compatibility with Mercedes-Benz Actros

The Mercedes-Benz Actros, one of the most popular heavy-duty trucks in Germany, frequently uses the OM471 engine. The Actros is known for its advanced technology, driver comfort, and fuel efficiency, making it a staple for logistics companies like DHL and DB Schenker. The OM471 crankshaft ensures the engine delivers consistent power, whether navigating the autobahn or tackling hilly terrain in Bavaria.

For example, the Actros 1845 model, equipped with the OM471 engine, is designed for long-haul transport, offering up to 449 horsepower and exceptional torque. The crankshaft’s robust design supports the engine’s high output, ensuring smooth operation and minimal downtime. Volgen Power supplies OM471 crankshafts that are fully compatible with Actros models, allowing fleet operators to maintain peak performance.

Supporting Germany’s Logistics Industry

Germany’s logistics sector is one of the largest in Europe, with over 3 million trucks on the road and a logistics market valued at €270 billion in 2024, according to Statista. The OM471 crankshaft powers trucks that transport goods across the country and beyond, supporting industries like automotive, retail, and manufacturing. Its durability and efficiency help fleet operators reduce maintenance costs and improve delivery times, giving them a competitive edge.

Volgen Power understands the needs of Germany’s logistics industry, offering OM471 crankshafts that meet the demands of high-mileage operations. With a streamlined supply chain, Volgen Power ensures that replacement crankshafts are delivered quickly, minimizing downtime for busy fleets.

Why Choose Volgen Power for OM471 Crankshafts

- OEM-Quality Assurance: Volgen Power’s OM471 crankshafts are manufactured to meet or exceed Mercedes-Benz’s OEM specifications. Each crankshaft undergoes rigorous quality control, ensuring compatibility with the OM471 engine and Euro-6 standards. This guarantees that your trucks maintain optimal performance and compliance, even under heavy use.

- Fast and Reliable Supply Chain: Downtime is costly in the logistics industry, and Volgen Power is committed to minimizing disruptions. With strategically located warehouses and partnerships with leading logistics providers, Volgen Power offers rapid delivery across Germany. Whether you’re in Berlin, Frankfurt, or Stuttgart, you can rely on Volgen Power to deliver OM471 crankshafts when you need them.

- Expert Support for German Customers: Volgen Power’s team of experts is well-versed in Mercedes-Benz engine technology and the needs of the German trucking industry. From selecting the right crankshaft to providing installation guidance, Volgen Power offers personalized support to ensure customer satisfaction. Their multilingual team can assist in German, English, and other languages, making the purchasing process seamless.

By choosing Volgen Power, you’re not just buying a crankshaft—you’re investing in reliability, efficiency, and peace of mind for your fleet.

How to Maintain Your OM471 Crankshaft

Proper maintenance is essential to maximize the lifespan of your OM471 crankshaft and ensure optimal engine performance. Below are key tips for maintaining your crankshaft:

Routine Maintenance Tips

- Regular Lubrication: Use high-quality engine oil recommended by Mercedes-Benz to reduce friction and wear on the crankshaft. Check oil levels regularly and replace oil according to the manufacturer’s schedule.

- Inspect Bearings: The crankshaft’s main and rod bearings should be inspected for wear during routine maintenance. Replace worn bearings promptly to prevent damage to the crankshaft.

- Monitor Vibration: Excessive vibration can indicate misalignment or imbalance in the crankshaft. Use diagnostic tools to detect issues early and address them before they escalate.

- Cleanliness: Keep the engine bay clean to prevent debris from entering the crankshaft assembly, which could cause abrasion or damage.

Common Issues and Solutions

- Crankshaft Wear: Over time, high-mileage trucks may experience wear on crankshaft journals. Solution: Use precision-ground crankshafts from Volgen Power to restore performance.

- Oil Leaks: Improper seals can lead to oil leaks around the crankshaft. Solution: Replace seals during maintenance and ensure proper installation.

- Vibration Issues: Imbalanced crankshafts can cause engine vibration. Solution: Have the crankshaft balanced by a professional or replace it with a Volgen Power OEM-quality unit.

Volgen Power offers maintenance guides and technical support to help German customers keep their OM471 crankshafts in top condition. Their team can also recommend compatible lubricants and replacement parts to simplify maintenance.

Case Study: Volgen Power’s OM471 Crankshafts in Action

In 2024, a leading logistics company in Hamburg faced a challenge: several of their Mercedes-Benz Actros trucks, powered by OM471 engines, required crankshaft replacements due to high mileage. The downtime was a major concern, as the company relied on these trucks for time-sensitive deliveries across Europe. They turned to Volgen Power for a solution.

Volgen Power delivered OEM-quality OM471 crankshafts within 48 hours, enabling the company to quickly replace the components and get its trucks back on the road. The crankshafts performed flawlessly, ensuring the trucks’ Euro-6 compliance and maintaining their fuel efficiency. The logistics company reported a 20% reduction in maintenance costs compared to previous suppliers, thanks to Volgen Power’s competitive pricing and reliable support.

This case study demonstrates Volgen Power’s ability to meet the needs of Germany’s logistics industry, delivering high-quality parts with minimal disruption.

FAQs.

Where can I buy an OM471 crankshaft in Germany?

Volgen Power is a trusted supplier of OEM-quality OM471 crankshafts in Germany, offering fast delivery to cities like Berlin, Munich, and Hamburg. Their robust supply chain minimizes downtime, and their team provides expert support in German and English.

How do I maintain an OM471 crankshaft for long-haul trucking?

Regular maintenance includes using Mercedes-Benz-recommended engine oil, inspecting main and rod bearings for wear, monitoring vibration, and keeping the engine bay clean to prevent debris damage. Volgen Power offers maintenance guides and technical support to help German customers extend the lifespan of their OM471 crankshafts.

What is the cost of an OM471 crankshaft in Germany?

The cost of an OM471 crankshaft varies based on whether it’s new or rebuilt, but Volgen Power offers competitive pricing for OEM-quality units. For an accurate quote, contact Volgen Power with your specific requirements. Their transparent pricing helps German fleet operators manage budgets effectively.

Is the OM471 crankshaft compatible with the Mercedes-Benz Actros?

Yes, the OM471 crankshaft is specifically designed for the OM471 engine, widely used in Mercedes-Benz Actros models like the Actros 1845. It ensures seamless integration, delivering the power and reliability needed for Germany’s long-haul routes. Volgen Power’s crankshafts are fully compatible with Actros trucks.