The Volvo I-SHIFT repair kit is an essential solution for keeping Volvo trucks operational, reducing downtime, and extending gearbox life. The I-SHIFT transmission—an automated manual transmission (AMT) system—has become a benchmark in heavy-duty trucking for its balance of fuel efficiency, driver comfort, and mechanical durability.

But even the most advanced gearbox requires maintenance. Wear on synchronizers, seals, bearings, and control components can cause performance issues over time. That’s where a high-quality Volvo I-SHIFT repair kit comes in, giving fleet operators and repair shops all the necessary components to restore optimal performance.

At Volgen Power, we specialize in supplying OEM-standard and premium aftermarket Volvo gearbox parts, ensuring your fleet stays on the road and your repair turnaround times remain competitive.

Table of Contents

Understanding the Volvo I-SHIFT Gearbox

The Volvo I-SHIFT is a computer-controlled AMT that blends the fuel efficiency and robustness of a manual gearbox with the convenience of an automatic. It uses a conventional manual transmission layout—complete with a dry clutch—but integrates electronic shift controls and pneumatic actuators to automate gear changes.

Key Features:

- Fuel Economy: Up to 5% better than traditional manuals.

- Smooth Shifting: Consistent gear changes under varying loads.

- Driver Comfort: Reduces fatigue on long hauls.

- Durability: Designed for 1 million km+ service life under proper maintenance.

How It Works

- Gear Selection Logic: Based on inputs from the engine control unit (ECU), vehicle speed sensors, and load sensors.

- Shift Execution: Pneumatic actuators move the shift forks, engaging gears without driver input.

- Clutch Control: An electronically controlled actuator engages/disengages the clutch.

- Adaptive Modes: Adjusts shift patterns for terrain, load, and driving style.

For detailed technical specifications, refer to Volvo Trucks I-SHIFT official documentation.

Common I-SHIFT Failures and Why Repair Kits Are Needed

Even the robust I-SHIFT can develop issues after hundreds of thousands of kilometers. Here are the most frequent problems:

| Symptom | Likely Cause | Repair Kit Solution |

|---|---|---|

| Delayed gear shifts | Worn synchronizer rings | Replace synchronizers |

| Oil leakage | Damaged seals or gaskets | Replace seal/gasket set |

| Gear noise | Worn or pitted bearings | Replace bearing set |

| ECU fault codes | Damaged connectors or wiring | Replace ECU connectors |

| Gear slipping | Worn shift fork bushings | Replace bushings |

Case Study:

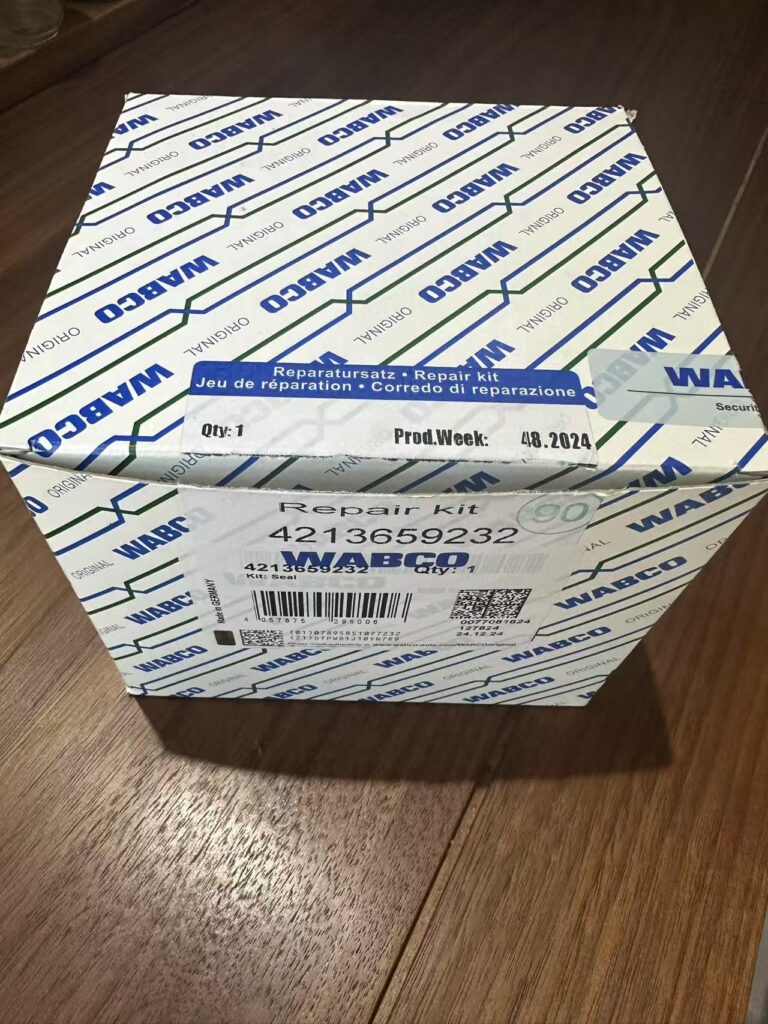

A Middle Eastern freight company operating 25 Volvo FH trucks experienced oil leaks and noisy shifts in several vehicles. By switching to Volgen Power’s premium I-SHIFT repair kits, they cut downtime per truck by 2 days and reduced gearbox-related maintenance costs by 28% annually.

Beyond the Middle Eastern freight company case, we’ve received positive feedback from North American clients: “Volgen Power’s Volvo I-SHIFT repair kit is top-notch quality, reducing our fleet downtime from 3 days per week to just 1, saving over 30% in maintenance costs.” – John Smith, Fleet Manager, US Logistics Inc. Another European customer shared: “When dealing with ‘Volvo I-SHIFT oil leakage repair,’ their kit was perfectly compatible, and performance was like new after installation.” These real testimonials highlight the reliability of our products.

What’s Inside a Volvo I-SHIFT Repair Kit

A complete kit typically includes:

| Component | Function | Material/Specification |

|---|---|---|

| Seals & Gaskets | Prevent fluid leaks and maintain pressure | High-temp rubber, steel-reinforced |

| Bearings | Support rotating shafts and reduce friction | Heat-treated alloy steel |

| Synchronizer Rings | Enable smooth gear engagement | Bronze alloy or carbon composite |

| Shift Fork Bushings | Guide shift forks during gear changes | High-wear polymer |

| Fasteners & Clips | Secure components in place | Stainless steel |

| ECU Connectors & Wiring | Maintain precise electronic communication | Automotive-grade wiring & terminals |

See our full inventory of Volvo gearbox parts here:

Volvo Gearbox Spare Parts – Volgen Power

Technical Analysis: I-SHIFT vs. Other AMTs

To understand why the Volvo I-SHIFT repair kit is so critical, let’s compare it to other AMT systems:

| Feature | Volvo I-SHIFT | ZF TraXon | Eaton UltraShift |

|---|---|---|---|

| Fuel Efficiency | Excellent | Excellent | Good |

| Shift Smoothness | Very High | High | Moderate |

| Component Durability | High | High | Moderate |

| Parts Availability | Widely available | Limited outside EU | Limited outside the EU |

| Maintenance Complexity | Medium | Medium-High | Medium |

Key Insight:

Volvo’s I-SHIFT tends to have longer synchronizer and bearing lifespans, but seal and gasket failures are common after 500,000–700,000 km, making repair kits a predictable maintenance item.

Global Market Overview & Price Trends

Demand for Volvo I-SHIFT repair kits varies by region:

Europe:

- High concentration of Volvo FH & FM trucks.

- Strong preference for OEM-standard parts.

- Price range: USD 450–$1,000 per kit.

Middle East & Africa:

- Heavy use in long-haul and desert operations.

- Higher wear rates due to heat and dust.

- Price range: USD 380$850 per kit.

North & South America:

- Growing adoption in freight and construction fleets.

- Mix of OEM and high-quality aftermarket kits.

- Price range: USUSD 400900 per kit.

Asia-Pacific:

- Price-sensitive market.

- Demand for competitive aftermarket solutions.

- Price range: USD 350–$750 per kit.

Price Tier Comparison Table:

| Tier | Price Range | Typical Buyer | Notes |

|---|---|---|---|

| OEM Genuine Volvo | $700–$1,000 | Authorized dealers, fleets with OEM-only policies | Highest quality, higher cost |

| Premium Aftermarket (Volgen Power) | $400–$700 | Fleets, independent repair shops | OEM-level quality, competitive price |

| Low-cost Aftermarket | $300–$500 | Price-driven buyers | Lower material durability |

Based on the latest 2025 market trends, with global supply chain recoveries and fluctuations in raw material costs, the Volvo I-SHIFT repair kit price in Europe has stabilized at USD 450–$1,100, while in the Middle East’s extreme environments, due to higher wear rates, the price range adjusts to USD 380–$900. In the Asia-Pacific region, surging demand has led to a 10% average price increase, now standing at USD 350–$800. This reflects the post-pandemic resurgence in the logistics industry and a growing preference for premium aftermarket parts.

Procurement Guide: How to Source the Right Volvo I-SHIFT Repair Kit

Choosing the right repair kit is more than just matching a brand name—it’s about ensuring precision fit, durability, and supplier reliability. For B2B buyers, mistakes in procurement can cause costly delays.

Step 1: Identify the Exact Gearbox Model

- Check the gearbox serial plate (usually located on the side of the transmission housing).

- Record both model code (e.g., AT2612F, ATO3112D) and serial number.

- Match with your supplier’s catalog to ensure compatibility.

Step 2: Verify Part Numbers

- Cross-reference Volvo OEM part numbers with aftermarket equivalents.

- Ensure seals, synchronizers, and bearings match your gearbox generation.

Step 3: Evaluate Supplier Capability

- Inventory Depth: Does the supplier keep full kits in stock or source on demand?

- Global Shipping Experience: Can they handle customs and export documents efficiently?

- Technical Support: Availability of installation guidance or troubleshooting.

B2B Negotiation Tips

- Bulk Purchase Discounts: Negotiate better unit pricing for orders of 10 kits or more.

- Service-Level Agreement (SLA): Define delivery timelines and penalties for delays.

- Warranty Terms: Ensure parts are covered for at least 12 months or a mileage equivalent.

- After-Sales Support: Confirm availability of replacement components if needed.

Installation & Maintenance Best Practices

While the Volvo I-SHIFT repair kit is designed to make overhauls straightforward, following proper procedures ensures maximum component lifespan.

Tools Required

- Torque wrench

- Bearing puller

- Seal installer

- Pneumatic line disconnect tool

- Volvo-approved diagnostic scanner

Installation Procedure

- Safety First: Disconnect battery power to prevent ECU interference.

- Drain Transmission Fluid: Use approved disposal methods.

- Disassemble Gearbox Housing: Follow Volvo service manual torque sequences.

- Inspect All Components: Identify any wear beyond kit contents.

- Replace Seals, Gaskets, Bearings: Use new components from the kit only.

- Reassemble with Correct Torque: Refer to Volvo torque specifications.

- Refill with Approved Gearbox Oil: See Volvo lubricant specifications.

- Calibrate ECU: Reset adaptation values to match the rebuilt gearbox.

Maintenance Intervals

- Oil Change: Every 300,000–400,000 km or per manufacturer’s guidelines.

- Seal Inspection: Every 200,000 km or annually in high-heat regions.

- Bearing Noise Check: During scheduled maintenance, use a stethoscope tool.

Volgen Power’s Global Shipping & Logistics

We supply Volvo I-SHIFT repair kits to over 30 countries and have specialized expertise in export compliance and fast delivery.

Our Advantages:

- Strong Inventory: Ready-to-ship kits for all major I-SHIFT models.

- Flexible Shipping: Air freight, sea freight, express courier.

- Customs Documentation: Complete paperwork for smooth clearance.

- Multi-Currency Payments: USD, EUR, CNY.

FAQs.

Q1: Are your Volvo I-SHIFT repair kits compatible with all I-SHIFT gearboxes?

A: We stock kits for all major models, including AT, ATO, and dual-clutch I-SHIFT variants. Provide your gearbox serial number for confirmation.

Q2: Do you supply only OEM parts?

A: We offer both genuine OEM kits and premium aftermarket kits built to OEM specifications.

Q3: Can I install the kit myself?

A: Professional installation is strongly recommended due to the complexity of gearbox disassembly and calibration.

Q4: Do you offer emergency shipping?

A: Yes, express shipments can be dispatched within 24 hours for urgent repairs.

Q5: How long does the kit last?

A: With proper maintenance, key components can last 500,000–800,000 km.

Expert Recommendations

Our transmission specialists recommend:

- Proactive Maintenance: Replace seals and synchronizers before complete failure to avoid damaging other components.

- OEM or Premium Quality Only: Low-grade parts can shorten gearbox life.

- Keep Spare Kits in Stock: Reduces downtime during unexpected failures.

- Use Approved Fluids: The wrong lubricant can accelerate wear.

Conclusion: Why Choose Volgen Power

With years of experience supplying heavy-duty transmission parts globally, Volgen Power offers the reliability, speed, and technical expertise that B2B customers require.

When you choose our Volvo I-SHIFT repair kits, you benefit from:

- OEM-standard quality at competitive pricing.

- Ready inventory and fast global delivery.

- Technical support from experienced specialists.

- Proven track record in Europe, the Middle East, Africa, and the Americas.