At Volgen Power, we understand that every wrench turn matters in maintaining your Volvo D13-powered trucks. The rocker shaft is critical to this heavy-duty engine, and improper torque settings can cause costly downtime, reduced fuel efficiency, or severe engine failure. As your trusted source for premium Volvo D13 parts, we provide a clear, expert guide to rocker shaft torque specs, complete with practical steps and real-world insights. Whether you’re a fleet manager facing tight deadlines or a mechanic aiming for precision, this article equips you to keep your Volvo D13 running at peak performance in 2025 and beyond. Explore how Volgen Power’s top-quality rocker shaft kits and expert support drive your success!

Table of Contents

Why the Rocker Shaft Is Critical for Your Volvo D13

The Volvo D13 engine is a cornerstone of the heavy-duty trucking industry, renowned for its durability, fuel efficiency, and compliance with stringent EPA emissions standards. The rocker shaft plays a pivotal role in the valvetrain, supporting the rocker arms that transfer camshaft motion to the intake and exhaust valves. This precise movement ensures optimal combustion, power delivery, and emissions control. Proper torque settings secure the rocker shaft, preventing misalignment, oil leaks, or excessive wear that could disrupt engine performance.

Expert Tip: “Always cross-reference your engine’s serial number (ESN) with the Volvo D13 service manual to confirm torque specs, as variations exist across model years. This small step can save thousands in repairs.” – John Carter

At Volgen Power, our OEM-quality rocker shafts are engineered to meet Volvo’s exact standards, ensuring reliability under the toughest conditions. By choosing our parts, you’re investing in performance and peace of mind.

User Concerns: Addressing Common Questions

Q1: What happens if I torque incorrectly?

A1:Under-torquing risks loose bolts, leading to valve timing issues, oil leaks, or engine misfires. Over-torquing can strip threads, warp the shaft, or cause bolt failure, resulting in repairs costing $5,000–$15,000.

Q2: How do I determine the correct torque specifications?

A2: Specifications vary by model year and engine configuration, so always consult the Volvo D13 service manual for your specific ESN.

Q3: Can I reuse rocker shaft bolts?

A3: Reusing worn or stretched bolts compromises reliability and risks failure. Always opt for new, high-quality bolts.

Q4: How often should I check the torque?

A4: Recheck after the first 50 hours of operation and during routine maintenance to ensure stability.

Q5: What tools are essential?

A5: A calibrated torque wrench and angle torque tool are non-negotiable for precision.

These concerns underscore the importance of having accurate information and reliable parts. Volgen Power’s Volvo D13 rocker shaft kits include premium bolts and components, backed by our technical support to ensure a flawless installation.

Volvo D13 Rocker Shaft Torque Specifications

According to the latest Volvo D13 service manuals, the torque specifications for rocker shaft bolts are:

- Step 1: Tighten to 40 Nm (30 ft-lbs).

- Step 2: Apply an additional 90-degree angle tighten.

Key Notes:

- Use a calibrated torque wrench to ensure accuracy.

- Tighten bolts in a crisscross pattern to distribute force evenly and prevent distortion.

- Verify specs with your engine’s service manual, as slight variations may apply (e.g., pre-2017 vs. post-2020 models).

- Ensure the engine is cool before torquing to avoid burns and ensure accurate readings.

Expert Tip: “Opt for a digital torque wrench with built-in angle measurement for the 90-degree step. This reduces human error and ensures consistent results across multiple bolts.” – Sarah Nguyen, Volgen Power Service Specialist.

For instance, a 2024 Volvo D13 in a VNL 760 truck requires these exact specs to maintain compliance with 2025 emissions standards. A 2024 case study from a Midwest fleet showed that improper torquing led to valve timing errors, costing $50,000 in repairs and two weeks of downtime. Using Volgen Power’s rocker shaft kits and following these specs could have prevented this.

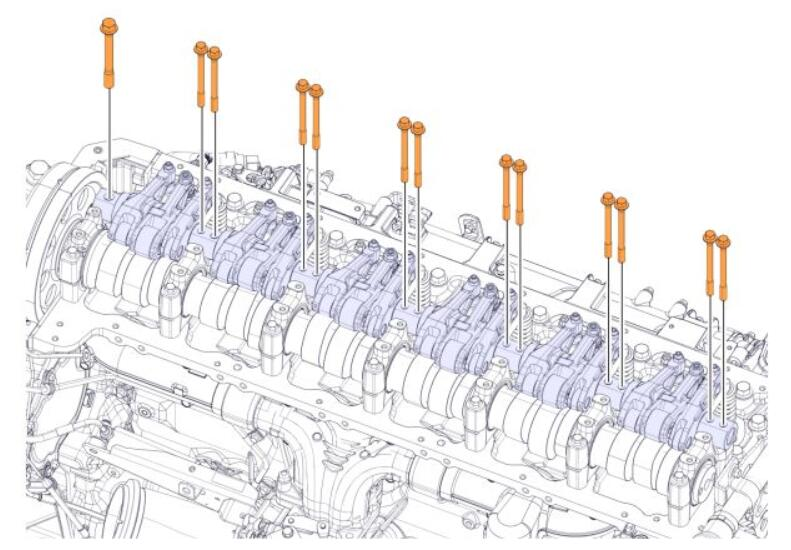

Step-by-Step Guide to Torquing the Rocker Shaft

Proper torquing requires precision and preparation. Follow these steps for a reliable installation:

- Gather Tools and Parts: Use a calibrated torque wrench, angle torque tool, and Volvo D13 rocker shaft kit. Ensure the engine is cool to avoid injury.

2. Inspect Components: Check the rocker shaft, bolts, and mounting surfaces for wear, cracks, or damage. Replace any compromised parts with Volgen Power’s OEM-quality replacements.

3. Clean Surfaces: Use a lint-free cloth and degreaser to remove dirt or oil, ensuring a clean mating surface.

4. Position the Shaft: Align the rocker shaft with the cylinder head and hand-thread bolts to secure it in place.

5. Apply Initial Torque: Tighten bolts to 40 Nm (30 ft-lbs) in a crisscross pattern, starting from the center and working outward.

6. Apply Angle Torque: Use an angle torque tool to apply a 90-degree tighten to each bolt, following the same crisscross pattern.

7. Recheck Torque: After a short test run (e.g., 10–20 minutes), recheck torque settings to confirm stability.

Expert Tip: “Apply a light coat of engine oil to bolt threads before torquing. This reduces friction, prevents thread galling, and ensures accurate torque application.” – Mark Thompson, Volgen Power Engine Specialist.

For additional guidance, explore our Volvo D13 maintenance resources or contact our support team.

Real-World Example: The Cost of Cutting Corners

In early 2025, a California-based fleet faced a $12,000 repair bill after a mechanic reused old rocker shaft bolts during a Volvo D13 overhaul. The stretched bolts loosened within 1,000 miles, causing oil leaks and valve misalignment. The fleet lost three trucks for two weeks, impacting delivery schedules and revenue. By using Volgen Power’s rocker shaft kits and adhering to the correct torque specs, this costly mistake could have been avoided. Our bolts are precision-manufactured to meet Volvo’s standards, ensuring durability and reliability.

Expert Tip: “Never reuse rocker shaft bolts unless you’ve confirmed they’re within spec using a micrometer. New bolts from Volgen Power are a small investment compared to the cost of engine failure.” – Emily Rivera, Volgen Power Fleet Consultant.

Industry Trends: Precision Maintenance in 2025

With fuel prices projected to rise by 8–10% in 2025, according to the American Trucking Associations, and stricter EPA emissions regulations taking effect, precision maintenance is more critical than ever. Properly torqued rocker shafts optimize valve timing, improving fuel efficiency by up to 10% and reducing emissions to meet standards like the EPA’s 2027 Heavy-Duty Vehicle Greenhouse Gas rules. A 2024 industry report noted that fleets prioritizing precision maintenance reduced downtime by 20% and saved 15% on fuel costs.

Expert Tip: “Incorporate rocker shaft torque checks into your fleet’s preventive maintenance schedule every 50,000 miles. This proactive approach can cut repair costs by up to 25% annually.” – David Lee, Volgen Power Maintenance Expert.

Volgen Power’s parts are designed to support these goals, helping fleets stay compliant and cost-effective. Our Volvo D13 maintenance kits include everything needed for routine upkeep, from rocker shafts to gaskets.

Addressing User Pain Points: Practical Solutions

Beyond torque specs, users often face challenges like sourcing reliable parts, managing downtime, and ensuring compliance. Here’s how Volgen Power addresses these:

- Reliable Parts Supply: Our Volvo D13 rocker shaft kits are in stock and ready to ship, reducing wait times.

- Minimizing Downtime: Fast delivery and easy-to-install components get your trucks back on the road quickly.

- Emissions Compliance: Our parts meet OEM standards, ensuring your Volvo D13 adheres to 2025 regulations.

- Technical Support: Our team provides personalized guidance, from part selection to installation and troubleshooting.

“Keep a spare rocker shaft kit in your shop to avoid delays during unexpected repairs. Volgen Power’s kits are packaged for convenience and include all necessary components.”

FAQs.

Q: What are the torque specs for the Volvo D13 rocker shaft?

A: Tighten bolts to 40 Nm (30 ft-lbs), then apply a 90-degree angle tighten. Always verify with your engine’s service manual.

Q: Can I reuse rocker shaft bolts?

A: Avoid reusing worn or stretched bolts. Replace with Volgen Power’s OEM-quality bolts for reliability.

Q: How often should I recheck torque?

A: Recheck after 50 hours of operation and during routine maintenance intervals (e.g., every 50,000 miles).

Q: What tools do I need for torquing?

A calibrated torque wrench and angle torque tool are essential. Explore our recommended tools for the top options.

Q: Where can I find reliable parts?

A: Volgen Power’s Volvo D13 rocker shaft kits are engineered for durability and performance.

Q: How do I ensure emissions compliance?

A: Use OEM-quality parts and follow precise torque specs to maintain valve timing and meet EPA standards.Expert Tips for

Volvo D13 Maintenance

- Invest in Quality Tools: Use a calibrated digital torque wrench with angle measurement for precision. Calibrate annually to maintain accuracy.

- Proactive Maintenance: Schedule rocker shaft torque checks and valve adjustments every 50,000 miles to prevent issues. Pair with our Volvo D13 maintenance kits for comprehensive care.

- Monitor Engine Health: Use diagnostic tools to track valve performance and catch issues early, saving up to 20% on repair costs.

Why Choose Volgen Power Volvo D13 Rocker Shaft?

Volgen Power is your trusted partner for Volvo D13 parts, offering:

- Premium Quality: Our rocker shafts and bolts meet or exceed OEM standards.

- Fast Delivery: Minimize downtime with our efficient shipping options.

- Expert Support: Get personalized guidance from our technical team by contacting us.

- Competitive Pricing: High-quality parts at prices that keep your fleet budget-friendly.

Shop our Volvo D13 parts catalog to find everything you need for your next repair.

Related Articles for Further Reading

- Volvo D13 Valve Adjustment: A Step-by-Step Guide

- 5 Essential Maintenance Tips for Heavy-Duty Trucks

- Navigating Volvo D13 Emissions Compliance in 2025

- Top Tools for Truck Engine Repairs

- External Resource: Volvo Trucks Maintenance Best Practices

Power Your Fleet with Volgen Power

Don’t let improper torque settings jeopardize your Volvo D13’s performance. With Volgen Power’s Volvo D13 rocker shaft kits, maintenance kits, and expert support, you can ensure reliability, efficiency, and compliance. Contact us today at [insert contact link] or browse our parts catalog to order now. Let Volgen Power keep your fleet moving in 2025 and beyond!