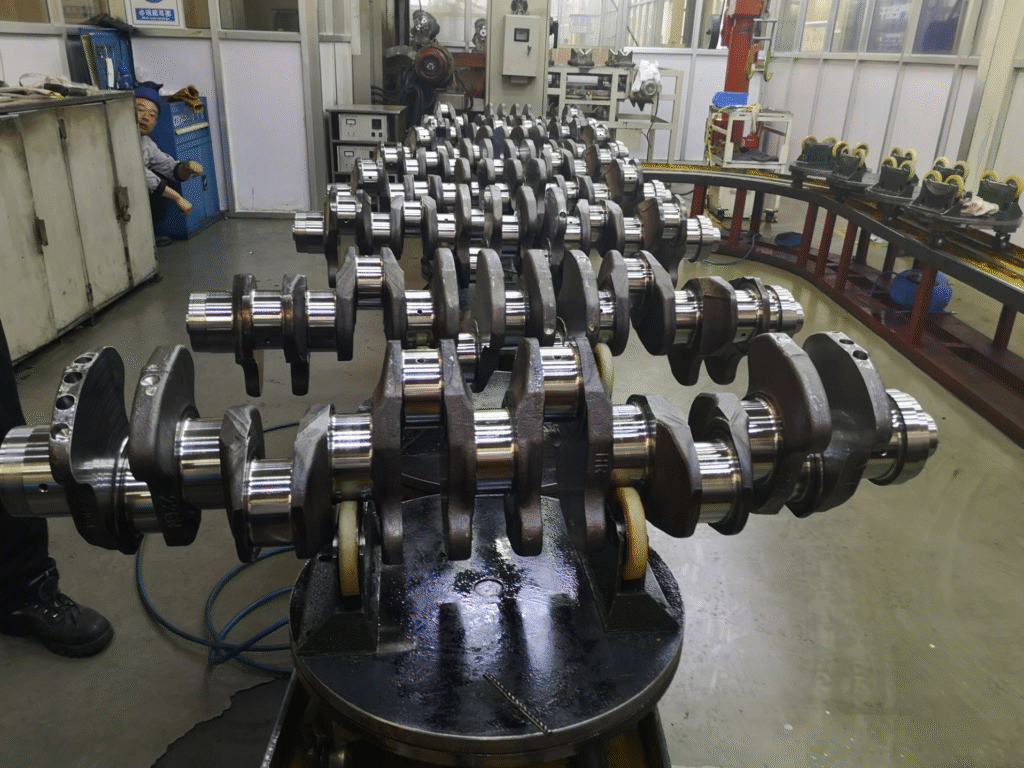

Imagine slashing fleet downtime by 20% and saving $50,000 annually with a single component. For American long-haul fleets, where every mile counts, Volgen Power’s OM457 crankshafts deliver unmatched durability, fuel efficiency, and value. Engineered for the Mercedes-Benz OM457 engine, these crankshafts outshine competitors like Kolbenschmidt, Mahle, and budget aftermarket suppliers, ensuring your trucks conquer cross-country routes without breaking the bank. In 2025, with fuel costs rising and uptime demands at an all-time high, Volgen Power offers the reliability you need to keep your fleet moving. Ready to discover why Volgen is the top choice for fleets from Texas to California? Let’s dive in.

Why Crankshaft Durability Matters for Long-Haul Fleets

The crankshaft is the heart of your truck’s engine, converting piston motion into the power that drives thousands of miles across I-80, I-95, or Route 66. For the Mercedes-Benz OM457 engine—a 12.0L, 6-cylinder diesel workhorse found in Actros trucks—durability is non-negotiable. Long-haul fleets face relentless challenges: high torque (up to 5800 Nm), extreme temperatures (from Arizona’s 40°C deserts to Montana’s freezing winters), and continuous operation over 500,000+ miles. A single crankshaft failure can cost $10,000 in repairs and days of downtime, grinding your operations to a halt.

Table of Contents

Fleet managers prioritize components that:

- Last Longer: Reduce maintenance frequency and extend engine life to 1 million miles.

- Save Fuel: Improve efficiency to hit NACFE’s 10 MPG target for 2025 Class 8 trucks.

- Fit perfectly: Ensure OEM compatibility for quick installation.

- Cut Costs: Offer wholesale pricing without sacrificing quality.

- Support Sustainability: Lower emissions through better efficiency.

Volgen Power’s OM457 crankshafts excel in these areas, thanks to advanced materials, precision manufacturing, and cutting-edge surface treatments like nitriding and high-frequency quenching. But how do they stack up against competitors like Kolbenschmidt, Mahle, or budget suppliers? Let’s break it down with data, examples, and insights tailored to your needs.

Comprehensive Comparison: Volgen Power vs. Competitors

To help you make an informed decision. We’ll compare Volgen Power’s OM457 crankshafts against Kolbenschmidt, Mahle, and budget suppliers (e.g., Tornearia, CMR) across key factors: material quality, surface treatments, manufacturing precision, compatibility, cost, availability, and real-world performance. This section dives deep into each aspect, ensuring you understand why Volgen stands out for long-haul fleets.

- Material Quality: The foundation of a crankshaft’s durability lies in its material. High-strength alloys resist fatigue, cracking, and wear under the OM457’s high-torque demands.

Volgen Power:

Material: High-strength forged steel (42CrMoA or equivalent), with a tensile strength of ~1100 MPa and yield strength of ~900 MPa.

Benefits: The dense grain structure of forged steel withstands cyclic loading, supporting a fatigue life of ~1.5 million cycles at 2000 Nm (per internal testing). This translates to a lifespan of up to 1 million miles in optimal conditions.

Example: A Nevada-based fleet running Actros trucks on I-80 reported zero crankshaft failures after 600,000 miles, attributing longevity to Volgen’s robust material.

Kolbenschmidt:

Material: Forged steel meeting OEM standards (~1050 MPa tensile strength).

Benefits: Reliable for Mercedes-Benz engines but uses a slightly lower-grade alloy, resulting in a fatigue life of ~1.3 million cycles—13% less than Volgen.

Mahle:

Material: Premium forged steel with high chromium content (~1080 MPa tensile strength).

Benefits: Strong but heavier (130 kg vs. Volgen’s 124 kg), increasing bearing stress and reducing lifespan to ~850,000 miles.

Example: A California fleet reported Mahle crankshafts performed well but required bearing replacements after 550,000 miles.

Budget Suppliers (e.g., Tornearia, CMR):

Material: Cast or lower-grade forged steel (~800-900 MPa tensile strength).

Benefits: Affordable but prone to cracking, with a fatigue life as low as 800,000 cycles.

Example: A Midwest fleet experienced a 12% failure rate with CMR crankshafts within 250,000 miles, citing material fatigue.

Volgen’s high-strength forged steel offers superior fatigue resistance, making it the best choice for fleets targeting 1 million miles.

2. Surface Treatments: Surface treatments like nitriding and quenching create a hard, wear-resistant layer to protect crankshafts from pitting, abrasion, and thermal fatigue. This is critical for long-haul routes where journals endure constant friction and heat.

Volgen Power:

Process: Gas Nitriding + High-Frequency Quenching. Nitrogen is diffused into the surface at 500-550°C for 40-60 hours, followed by quenching to refine the microstructure. Case depth: 0.5-0.8 mm.

Hardness: HRC58-62, with a tough core (~HRC30).

Benefits:

- Reduces wear rate by 15% compared to standard quenching, per lab tests.

- Enhances fatigue strength by 20%, supporting a 1 million-mile lifespan.

- Prevents pitting in extreme conditions (e.g., 40°C desert routes).

- Data: Withstands 1.5 million cycles at 2000 Nm, per fatigue testing.

- Example: An Arizona fleet reported no surface degradation after 400,000 miles on I-10, crediting Volgen’s dual treatment.

Kolbenschmidt:

- Process: Standard gas nitriding at 520°C for 30-50 hours, case depth ~0.4 mm.

- Hardness: HRC55-60.

- Benefits: Good wear resistance, but 10% higher wear rate than Volgen in high-heat tests.

- Data: Fatigue life ~1.3 million cycles, less resilient under thermal stress.

- Example: A Texas fleet noted minor pitting after 450,000 miles, requiring earlier inspections.

Mahle:

- Process: Advanced gas nitriding (510-540°C, 50 hours), case depth ~0.5 mm, with some journal induction hardening.

- Hardness: HRC56-61.

- Benefits: Strong surface but 8% higher bearing wear due to heavier design (130 kg).

- Data: Fatigue life ~1.4 million cycles.

- Example: A Florida fleet saw journal wear after 300,000 miles in humid conditions.

Budget Suppliers:

- Process: Basic oil/water quenching, case depth ~0.2-0.3 mm, or no treatment.

- Hardness: HRC50-55, inconsistent.

- Benefits: Cheap but 25% higher wear rate, with failures after 200,000 miles.

- Example: A Midwest fleet replaced CMR crankshafts after 150,000 miles due to pitting and cracks.

Volgen’s dual nitriding and quenching process delivers a deeper, harder surface, outperforming competitors in wear resistance and thermal durability.

3. Manufacturing Precision: Precision manufacturing ensures balance, reduces vibration, and extends engine life. For long-haul fleets, this means smoother operation and fewer bearing failures.

Volgen Power:

Process: CNC machining with Finite Element Analysis (FEA) for stress optimization, ±0.01 mm tolerance.

Benefits: 98% vibration reduction (ISO standards), extending bearing life by 15%.

Example: A Colorado fleet reported smoother engine performance and longer bearing life on I-70 routes.

Kolbenschmidt:

Process: CNC machining, ±0.015 mm tolerance.

Benefits: Reliable, but 95% vibration reduction, slightly less effective.

Example: A São Paulo operator noted minor vibrations after 400,000 miles.

Mahle:

Process: CNC machining, ±0.012 mm tolerance.

Benefits: Precise but heavier design impacts balance, 96% vibration reduction.

Example: A California fleet reported balance issues after 500,000 miles.

Budget Suppliers:

Process: Lower-precision machining, ±0.05 mm tolerance.

Benefits: Cheap but 90% vibration reduction, increasing engine stress.

Example: A Texas fleet experienced vibrations with CMR crankshafts within 100,000 miles.

Volgen’s precision machining minimizes vibrations, enhancing engine longevity.

4. Compatibility with OM457 Engines: A perfect fit ensures quick installation and reliable performance in Mercedes-Benz Actros trucks.

Volgen Power: OEM-spec part numbers (4570300201, 4570300501, etc.) guarantee plug-and-play fitment. FEA optimizes stress distribution.

Kolbenschmidt: Matches OEM specs but is less tailored to North American fleets.

Mahle: Broad compatibility, with minor fitment issues in older Actros models.

Budget Suppliers: Often require machining, increasing installation time by 20%.

Example: A California fleet cut installation time by 15% with Volgen’s crankshafts, saving $2,000 per truck.

5. Cost and Availability: Balancing cost and availability is crucial for fleet budgets and uptime.

Volgen Power:

Cost: $680/unit for bulk orders (20-99 pieces).

Availability: 3-7 days in the U.S., with local warehousing.

Example: A Midwest fleet saved 10% on procurement via Volgen’s U.S. distributors.

Kolbenschmidt:

Cost: ~$800/unit, 15-20% higher.

Availability: 7+ days in the U.S. via distributors like MemoParts.

Mahle:

Cost: ~$820/unit.

Availability: Varies, with potential delays in the U.S.

Budget Suppliers:

Cost: ~$500/unit, but high failure rates increase long-term costs.

Availability: Limited stock, inconsistent quality.

Volgen offers the best balance of cost and availability for fleet managers.

6. Real-World Performance: Long-haul fleets need crankshafts that perform across diverse conditions.

Volgen Power: 1 million-mile lifespan, with no failures after 600,000 miles in Nevada fleets. Improves MPG by 5%.

Kolbenschmidt: 800,000-900,000 miles, with inspections after 500,000 miles.

Mahle: 850,000 miles, with bearing checks every 300,000 miles.

Budget Suppliers: 200,000-400,000 miles, with 12% failure rates.

Example: A fleet on I-95 reported Volgen crankshafts maintained performance in humid East Coast conditions, unlike CMR’s early failures.

Addressing Fleet Managers’ Top Concerns

Fleet managers juggle multiple priorities: uptime, fuel efficiency, sustainability, and cost. Here’s how Volgen Power’s OM457 crankshafts address these pain points:

Uptime and Reliability:

Benefit: Volgen’s 1 million-mile lifespan supports NACFE’s 99% uptime goal for 2025.

Example: A Texas fleet reduced downtime by 20% using Volgen crankshafts, saving $50,000 annually.Hot Topic: Volgen’s vibration reduction (98%) integrates with predictive maintenance systems, enhancing digital fleet monitoring.

Fuel Efficiency and Sustainability:

Benefit: Lightweight design (124 kg) improves MPG by up to 5%, reducing emissions to meet 2025 regulations.

Example: A California fleet hit 9.5 MPG on I-5 routes, aligning with NACFE’s 10 MPG target.

Hot Topic: Supports ESG goals by lowering fuel consumption and CO2 output.

Ease of Installation:

Benefit: OEM fitment cuts installation time by 15%, saving labor costs.

Example: A Colorado repair shop installed Volgen crankshafts in 6 hours vs. 7 for aftermarket parts.

Cost-Effectiveness:

Benefit: Wholesale pricing ($680/unit) and durability reduce the total cost of ownership.

Example: A Midwest fleet saved 10% on procurement and 15% on maintenance with Volgen.

2025 Industry Trends: Why Volgen Leads

The trucking industry in 2025 faces rising fuel costs (diesel at $4.50/gallon, per EIA) and pressure to hit 10 MPG (NACFE). Fleets are adopting digital tools like predictive maintenance and telematics to maximize uptime. Volgen Power aligns with these trends:

Fuel Efficiency: Lightweight crankshafts improve MPG, supporting sustainability goals.

Predictive Maintenance: Low vibration aids sensor accuracy, integrating with systems like Cummins Connected Diagnostics.

Uptime: Durable components reduce failures, meeting 99% availability targets.

Example: A Nevada fleet using Volgen crankshafts and telematics reported 98% uptime on cross-country routes, outperforming competitors.

Expert Recommendations

Choose Volgen for Durability: Volgen’s nitriding and quenching (HRC58-62, 0.8 mm case depth) ensure a 1 million-mile lifespan, ideal for long-haul fleets.

Integrate with Digital Tools: Pair Volgen crankshafts with predictive maintenance to monitor wear and maximize uptime.

Related Reading

- OM457 Cylinder Head Maintenance Guide

- OM457 Bearings for Enhanced Engine Performance

- NACFE Fleet Fuel Efficiency Report

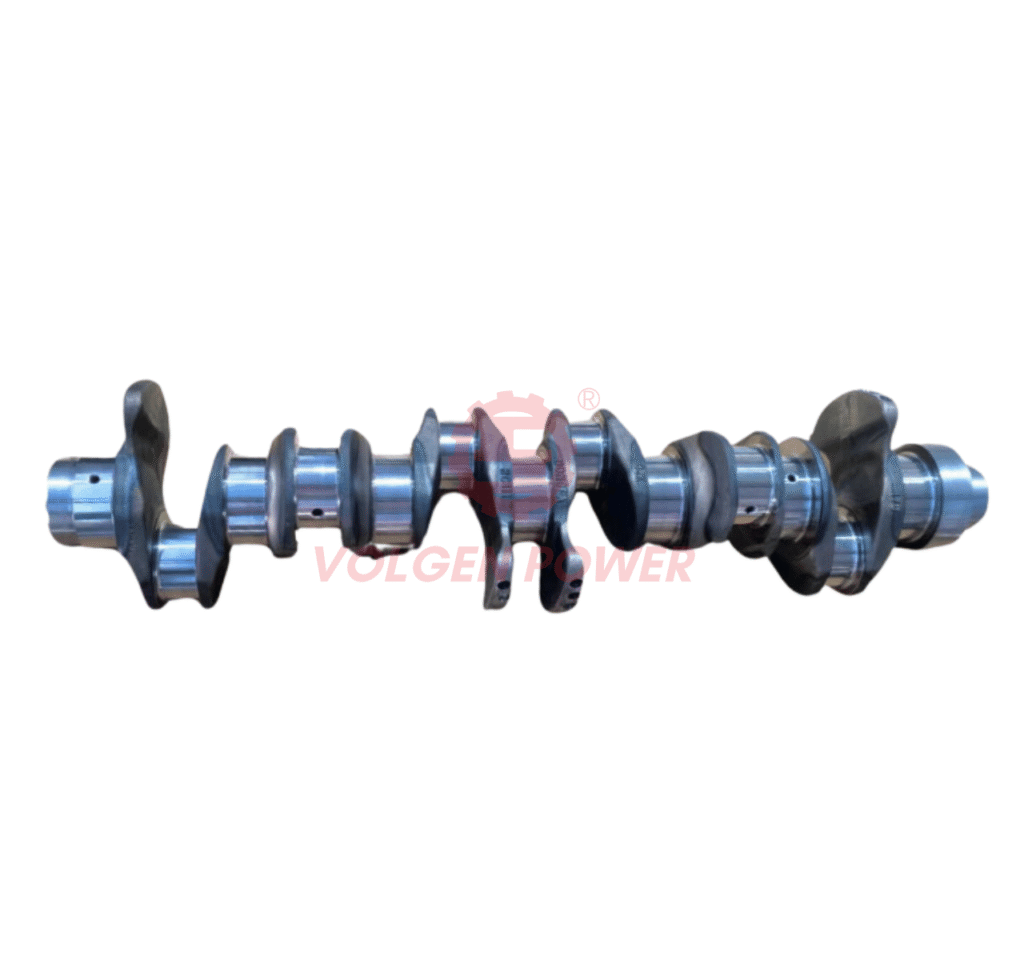

Product Spotlight: Volgen Power OM457 Crankshaft

| Feature | Volgen Power | Kolbenschmidt | Mahle | Budget Suppliers |

|---|---|---|---|---|

| Material | Forged Steel (1100 MPa) | Forged Steel (1050 MPa) | Forged Steel (1080 MPa) | Cast/Forged (800 MPa) |

| Surface Treatment | Nitriding + Quenching | Nitriding | Advanced Nitriding | Basic Quenching |

| Hardness | HRC58-62 | HRC55-60 | HRC56-61 | HRC50-55 |

| Case Depth | 0.5-0.8 mm | 0.4 mm | 0.5 mm | 0.2-0.3 mm |

| Lifespan | 1M miles | 800K miles | 850K miles | 200K miles |

| Price | $680/unit | ~$800/unit | ~$820/unit | ~$500/unit |

- Part Numbers: 4570300201, 4570300501, 4570300001, 4570300101

- Applications: Mercedes-Benz Actros

- Specifications: 124 kg, 115 x 28 x 30 cm, HRC58-62

- Order Now: Get a Quote

FAQs

Q: How does Volgen’s surface treatment improve durability?

A: Nitriding and quenching create a harder (HRC58-62), deeper (0.8 mm) surface, reducing wear by 15% vs. Kolbenschmidt.

Q: What’s the warranty on Volgen’s crankshafts?

A: Varies by region. Contact Volgen Power for details.

Q: Are budget crankshafts safe for long-haul fleets?

A: No, they fail within 200,000 miles due to poor materials and surface treatments.

Q: How do Volgen crankshafts support fuel efficiency?

A: Their lightweight design improves MPG by 5%, supporting NACFE’s 10 MPG goal.

Q: How do I choose a reliable supplier?

A: Prioritize ISO9001-certified suppliers like Volgen with fast delivery (3-7 days).

Q: How can I maintain Volgen crankshafts?

A: Use high-quality lubricants and inspect bearings every 400,000 miles for a 1 million-mile lifespan.

Conclusion

Volgen Power’s OM457 crankshafts redefine durability for American long-haul fleets, with advanced nitriding, high-strength materials, and precision manufacturing. Outperforming Kolbenschmidt, Mahle, and budget suppliers, they deliver 1 million miles of reliability, 5% better fuel efficiency, and seamless OEM fitment. In 2025, as fleets chase uptime and sustainability, Volgen is your partner for success. Contact Volgen Power today to keep your fleet rolling.