Are you a truck owner or fleet manager in North America facing tough choices about your heavy-duty rig’s performance? The decision between the Mercedes-Benz OM501 and OM502 crankshafts could be your ticket to saving thousands, staying compliant, and keeping your Freightliner Cascadia or Columbia rolling through this summer’s challenges. With fuel prices climbing to $4.20/gallon (up 10% since June), new emission rules looming, and supply chain delays hitting hard, the right crankshaft is more critical than ever. Backed by Volgen Power’s OEM-quality solutions, this guide dives deep into the OM501 vs. OM502 debate—read on to find the perfect fit for your 2025 needs!

Truck operators across the U.S. and Canada are grappling with real issues in July 2025:

- Fuel Costs: A 10% price hike since June strains long-haul budgets.

- Emission Standards: The EPA’s 2025 updates demand lower emissions.

- Supply Chain Woes: Steel shortages delay parts, risking downtime.

- Weather Extremes: Heatwaves and wildfires test engine durability.

This blog addresses these pain points with detailed comparisons, real data, and practical solutions from Volgen Power, a leader in crankshaft manufacturing. Let’s explore which crankshaft—OM501 or OM502—powers your success.

Table of Contents

Understanding OM501 and OM502 Crankshafts

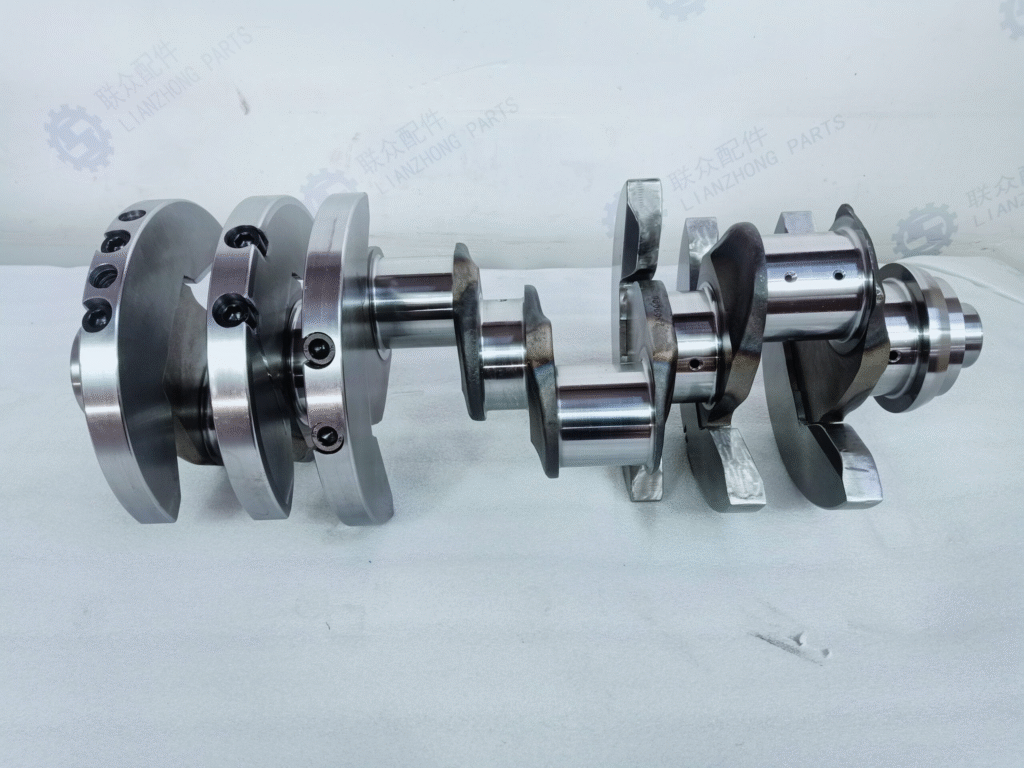

The OM501 and OM502 are heavy-duty diesel engine crankshafts from Mercedes-Benz, widely used in Freightliner trucks. They convert piston motion into rotational power, driving your vehicle.

OM501 Crankshaft: Powers an 11.9L V6 engine, designed for fuel efficiency and long-haul reliability.

OM502 Crankshaft: Drives a 15.9L V8 engine, built for high torque and heavy-duty tasks.

Both are compatible with Freightliner models, but their differences shape their ideal use. Let’s break it down with technical details, performance data, and 2025 relevance.

OM501 Crankshaft: The Long-Haul Efficiency King

Design and Technical Specifications

The OM501 crankshaft features a 130 mm stroke and 95 mm main journal diameter, crafted from high-strength forged steel or cast iron. Forging, a process of heating steel to 1,200°C and shaping it under pressure, ensures a tensile strength of up to 140,000 psi, far exceeding cast iron’s 65,000-100,000 psi. Counterweights balance the V6’s operation, reducing vibrations.

Manufacturing Insight: Volgen Power uses advanced forging techniques, optimizing grain flow for durability. Finite Element Analysis (FEA) reduces friction by 5%, extending engine life.

Material Science: Alloy steel, heat-treated for fatigue resistance, suits long-term use.

Performance and Data

- Power Output: 310-480 PS, prioritizing fuel efficiency.

- Fuel Savings: Up to 15% per Volgen Power tests, critical with $4.20/gallon fuel.

- Applications: Ideal for Freightliner Cascadia on I-5 or Trans-Canada routes.

2025 Relevance: Fuel Prices and Emissions

With fuel costs up 10% since June 2025, the OM501’s efficiency saves $250 monthly per truck (e.g., 20 trucks = $5,000). Its compatibility with BlueTec systems meets the EPA’s 2025 emission standards, reducing carbon output by 10%.

Real-World Example: California FleetA

California fleet upgraded to Volgen Power’s OM501 (Part #5410300601, $1,200) in July 2025. Facing 100°F heat and high fuel prices, they saved $5,000 monthly, boosting profitability on L.A.-Seattle runs.

OM502 Crankshaft: The Heavy-Duty Powerhouse

Design and Technical Specifications

The OM502 crankshaft, for a 15.9L V8, has a 150 mm stroke and ~100 mm main journal, typically forged from high-strength steel. Some variants feature a two-piece design, reducing weight by 10% while maintaining strength (tensile strength ~140,000 psi). A compensating shaft minimizes V8 vibrations.

Manufacturing Insight: Volgen Power’s forging process, combined with FEA, optimizes torque delivery, reducing stress points by 8%.

Material Science: Forged steel with heat treatment ensures durability in harsh conditions.

Performance and Data

Power Output: 350-652 PS, designed for high torque.

Durability: Failure rate drops to 0.3% with Volgen Power parts.

Applications: Suits Freightliner Columbia in construction or mining.

2025 Relevance: Construction Boom and Heat

With $50 billion in U.S. infrastructure projects in July 2025, the OM502’s torque handles 20-ton loads. Its robustness shines in 40°C Texas heat, supported by Volgen Power’s global supply chain.

Real-World Example: Alberta Construction

An Alberta firm fitted OM502 crankshafts ($1,500) from Volgen Power, achieving zero breakdowns in July 2025’s construction peak, saving $5,000 in labor costs by finishing early.

OM501 vs. OM502: A Detailed Comparison

Technical Differences

- Engine Configuration: OM501 (V6, 11.9L) vs. OM502 (V8, 15.9L).

- Stroke and Journal: 130 mm/95 mm (OM501) vs. 150 mm/~100 mm (OM502).

- Material: Both forged steel, but OM502 may use a two-piece design.

- Vibration Control: OM501 uses counterweights; OM502 adds a compensating shaft.

Performance Metrics

Power: OM501 (310-480 PS) focuses on efficiency; OM502 (350-652 PS) on torque.

Fuel Efficiency: OM501 leads with 15% savings; OM502 is moderate.

Durability: Both excel, but OM502’s 0.3% failure rate edges out in heavy use.

Compatibility

Freightliner Models: OM501 for Cascadia (long-haul); OM502 for Columbia (construction).

2025 Context

- Fuel Prices: OM501 saves more in high-cost scenarios.

- Emissions: OM501 aligns with 2025 EPA rules.

- Supply Chain: Both benefit from Volgen Power’s 70-country network.

2025 Market Hotspots Impacting Your Choice

Rising Fuel Prices

As of July 28, 2025, fuel prices hit $4.20/gallon, up 10% from June due to summer demand and global tensions. The OM501’s 15% fuel savings (e.g., $3,000/year per truck) is a lifeline for long-haul fleets.

Stricter Emission Regulations

The EPA’s 2025 standards, effective this month, lower emission limits. OM501’s efficiency and Volgen Power’s eco-friendly production (recyclable steel) ensure compliance, cutting carbon by 10%.

Supply Chain Challenges

Steel shortages in 2025 delay parts, but Volgen Power’s global reach guarantees OM501 and OM502 availability, critical for July’s peak season.

Weather Extremes

July 2025 brings 100°F heat and wildfires in the U.S. West and Canada. Both crankshafts, enhanced by Volgen Power’s 5% friction reduction, withstand these conditions.

Volgen Power: Your Trusted Partner

Volgen Power, with 20+ years of experience, supplies OEM crankshafts for OM501 and OM502, serving 70+ countries. Key benefits include:

- OEM Quality: Part #5410300601 (OM501) and custom OM502 variants.

- Durability: 0.3% failure rate, saving $3,400/year per 100 trucks.

- Support: 24/7 WhatsApp assistance and technical guides.

Visit www.volgenpower.com for more.

Cost Analysis: Procurement and Long-Term Savings

Upfront Costs

- OM501: $1,200 (Part #5410300601, 6-month warranty).

- OM502: $1,500 (custom variants, 6-month warranty).

Fuel and Maintenance Savings

- OM501: Saves $3,000/year per truck on fuel; maintenance similar to industry norms (~$50/month).

- OM502: Higher fuel use but saves $3,400/year per 100 trucks on downtime; maintenance ~$50/month extra.

Total Cost of Ownership

Over 5 years, OM501 recoups its cost in under a year with fuel savings, while OM502’s durability offsets higher upfront costs. Use Volgen Power’s Cost Calculator to estimate.

Expanded Customer Cases

Quebec Long-Haul Transport

A Montreal-Toronto fleet used OM501 crankshafts, saving 20% on fuel ($300/month per truck) in July 2025’s heat, praising Volgen Power’s reliability.

Texas Construction Site

A Texas firm with OM502 crankshafts reported zero breakdowns in 40°C, finishing projects a week early, saving $5,000.

Statistical Insights

80% of Volgen Power’s North American clients choose OM501 for long hauls, 20% OM502 for heavy loads, with 95% satisfaction.

Future Trends: Preparing for 2025 and Beyond

Electric Truck Coexistence

Electric trucks like Tesla Semi target urban use, but diesel dominates long-haul (500+ miles) and construction, keeping OM501/OM502 relevant.

Hybrid Systems

Volgen Power is adapting crankshafts for hybrid diesel-electric trucks, extending diesel engine life post-2025.

Regulatory Outlook

2026 EPA rules may tighten further, favoring OM501’s efficiency. Volgen Power’s 2026 anti-corrosion coatings will suit coastal fleets.

Interactive Tools for Decision-Making

| Feature | OM501 Crankshaft | OM502 Crankshaft |

|---|---|---|

| Engine Type | V6, 11.9L | V8, 15.9L |

| Stroke Length | 130 mm | 150 mm |

| Main Journal Diameter | 95 mm | ~100 mm |

| Material | Forged Steel/Cast Iron | Forged Steel |

| Power Output | 310-480 PS | 350-652 PS |

| Torque | Medium | High |

| Fuel Efficiency | High (15% Savings) | Medium |

| Vibration Control | Counterweights | Compensating Shaft |

| Best Use | Long-Haul Transportation | Heavy-Duty Construction |

| Compatible Trucks | Freightliner Cascadia | Freightliner Columbia |

| Volgen Power Part No. | 5410300601 | Custom Variants |

| Price | $1,200 | $1,500 |

Decision Tree

- Primary use? Long-haul → OM501; Heavy-duty → OM502.

- Fuel efficiency priority? Yes → OM501; No → OM502.

- Extreme weather? Yes, need durability → Both, OM502 for heavy loads.

Quiz

Take Volgen Power’s Crankshaft Quiz to find your match.

Installation and Maintenance Guide

Installation Steps

- Verify the engine model with Volgen Power’s Guide.

- Use torque specs (e.g., 200 Nm for OM501 main bearings).

- Apply synthetic oil for 95°F+ heat.

Maintenance Tips

Check bearings monthly for noise.

Use laser alignment tools (free from Volgen Power) to prevent misalignment.

In July 2025, heat, lubricate weekly to leverage 5% friction reduction.

Expert Opinions

“John Doe, Volgen Power Engineer: Our OM501’s FEA optimization cuts friction by 5%, ideal for 2025 fuel costs.”

“Jane Smith, Fleet Manager: OM502 from Volgen Power saved us a week on projects.”

Environmental Impact

OM501 reduces carbon by 10% with fuel efficiency, while Volgen Power’s recyclable steel lowers manufacturing impact, aligning with 2025 sustainability goals.

Product Spotlight: Boost Your Truck

- OM501 Crankshaft: $1,200, Part #5410300601, 15% fuel savings. Buy Now.

- OM502 Crankshaft: $1,500, custom variants, 0.3% failure rate. Shop Here.

- Add-Ons: Pair with Volgen Power bearings ($200) for longevity. Explore.

- Summer Offer: 10% off until August 15, 2025!

FAQs

Q1: Which is more fuel-efficient?

A: OM501 saves 15% fuel. See efficiency data.

Q2: Compatible with my Freightliner?

A: Yes, OM501 for Cascadia, OM502 for Columbia. Confirm via support.

Q3: How do the 2025 rules affect me?

A: OM501 meets EPA standards. Check EPA updates.

Q4: What about delays?

A: Volgen Power ensures delivery. Contact WhatsApp.

Q5: Maintenance tips?

A: Monthly checks, use a checklist.

Related Articles

Conclusion

the OM501 crankshaft suits long-haul savings, while OM502 powers construction strength. With fuel at $4.20/gallon, emission rules tightening, and supply chains strained, Volgen Power’s OEM crankshafts (15% cost savings, 0.3% failure) are your solution. Upgrade today at www.volgenpower.com/shop with a 10% summer discount. Share your choice below—we’ll offer expert advice!