The OM457 engine, widely used in heavy-duty vehicles like Mercedes-Benz trucks, is known for its durability but requires meticulous cylinder head maintenance to prevent issues like cracks and overheating. A cracked cylinder head can lead to costly repairs, downtime, and reduced engine performance. This guide, informed by industry expertise, outlines the common causes of cylinder head cracks, essential maintenance tips, cooling system care, and warning signs to watch for. Follow these steps to extend the life of your OM457 engine and avoid premature failures.

Table of Contents

Common Causes of OM457 Cylinder Head Cracks

Understanding why cylinder head cracks occur in OM457 engines is the first step to prevention. Below are the primary culprits, based on decades of diesel engine expertise:

Overheating and Thermal Stress

Rapid temperature changes—such as quick heating followed by cooling—cause the aluminum cylinder head to expand and contract. Over time, this thermal stress weakens the material, leading to cracks, especially in high-stress areas like between the valves.

Example: Prolonged operation in extreme conditions (e.g., desert heat or cold climates) exacerbates this issue.

High-Stress Operating Conditions

Heavy workloads, such as towing heavy loads or climbing steep inclines, place significant strain on the OM457 engine. These conditions increase cylinder head pressure, raising the risk of cracks.

Tip: Monitor engine load during demanding tasks and avoid overloading.

Temperature and Pressure Cycles

The OM457’s combustion chamber experiences constant high temperatures and pressures. These cycles gradually weaken the cylinder head material, particularly in aluminum heads, which are less tolerant of thermal stress.

Key Area: Cracks often form near valve seats due to their exposure to intense heat.

Improper Installation and Gasket Issues

Mistakes during maintenance, such as incorrect counterbore cuts, improper liner protrusion, or using the wrong head gasket, can cause compression leaks into the cooling system. This creates hot spots that lead to overheating and cracks.

Critical Note: OM457 cylinder heads post-engine number 085589 have different sealing surfaces (smooth vs. grooved). Always verify gasket compatibility to avoid catastrophic damage.

Material Weaknesses

The aluminum construction of OM457 cylinder heads makes them prone to cracking under excessive heat or stress. Unlike cast iron, aluminum is less forgiving of rapid temperature shifts.

Key Takeaway: Regular monitoring of operating conditions, adherence to OEM specs, and proper installation practices are critical to preventing OM457 cylinder head cracks.

Essential Maintenance Tips for OM457 Cylinder Heads

Proactive maintenance is the cornerstone of keeping your OM457 cylinder head in top condition. Follow these expert-recommended steps to prevent cracks, overheating, and premature wear:

Inspect and Retorque Cylinder Head Bolts

Periodically check cylinder head bolts for looseness, as loose bolts can cause head movement and stress. Retorque bolts to the manufacturer’s specifications during major services or after overheating incidents.

Pro Tip: Use a calibrated torque wrench to ensure precision.

Prevent Debris Contamination

During disassembly, cover all intake openings to prevent debris from entering the cylinder head. Dirt or particles can create hot spots, leading to overheating and cracks.

Best Practice: Use clean, lint-free cloths to cover openings.

Follow Proper Disassembly Procedures

Before removing the cylinder head, disconnect the exhaust manifold, scavenge manifold, cooling system, starter air system, and high-pressure fuel lines. Avoid forcing or stretching components to prevent damage.

Order of Removal: Rocker arms, valve yokes, pushrods, protective tubes, indicator valves, injectors, then the cylinder head (using hydraulic tools for head nuts).

Clean and Inspect Thoroughly

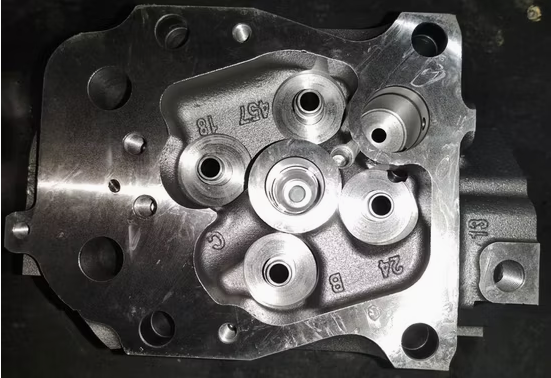

Use a chemical wash to remove carbon buildup, followed by compressed air to dry the head. Inspect for cracks, worn valve seats, or warping. Replace damaged valve seats to maintain a proper seal.

Inspection Tip: Use a magnifying glass to check for micro-cracks between valves.

Use New Sealing Components

Always install new gaskets and O-rings during reassembly. Reusing old seals risks coolant or oil leaks, which can cause overheating and cracks.

Example: A reused gasket may fail to seal properly, leading to compression loss.

Align Pressure Pipes and Seals

Ensure pressure pipe connections with anti-twist locks align perfectly with cylinder head grooves. Apply engine oil to connections to prevent leaks, and replace damaged anti-twist locks with updated fittings.

Torque Spec: Tighten leak fuel lines to 15 Nm for a secure seal.

Adhere to the OM457 Manual

Follow the manufacturer’s maintenance manual for torque specifications, bolt tightening sequences, and alignment steps. Incorrect tightening can cause uneven stress, a leading cause of cracks.

Resource: Refer to the official OM457 service manual for detailed instructions.

Recommended Maintenance Schedule:

- Valve Clearance Check: Every 20,000–40,000 km

- Cylinder Head Bolt Inspection: During major services or post-overheating

- Cooling System Check: Every 10,000–20,000 km

- Full Cylinder Head Overhaul: During major engine work or if symptoms (coolant loss, oil leaks, overheating, misfires) appear

Real-World Impact:

Replacing worn gaskets promptly prevents coolant-oil mixing, reducing crack risk.

Routine cleaning and valve seat inspections catch corrosion early, preventing cracks or warping.

Correct bolt tightening sequences ensure even pressure, minimizing stress fractures.

Expert Opinion:

“I’m a diesel engine specialist. I’ve worked with commercial engines for over 20 years. Based on my experience, proper maintenance for OM457 cylinder heads is extremely important. These maintenance steps aren’t just suggestions. They are vital practices. Following them can double your engine’s service life. I’ve examined hundreds of failed cylinder heads myself. In almost 80% of those cases, regular maintenance could have prevented the failure. For the OM457, the link between the cooling system’s condition and the head’s lifespan is very important. The OM457 head design is more sensitive to stress from heating and cooling cycles than some other engines, especially if maintenance is skipped. Following these detailed maintenance steps does more than just prevent a major breakdown. It helps keep your engine running at its best. It maintains fuel efficiency. And it reduces your overall cost to own and run the vehicle over its life.“

———— Robert Williams , Senior Diesel Engine Technician with Mercedes-Benz Commercial Vehicles and certified Master Diesel Technician with specialization in European heavy-duty engines

Cooling System Maintenance for OM457 Engines

Based on my experience, maintaining the cooling system is key to preventing overheating. It also protects your OM457 engine’s cylinder head from cracks and premature failure. Performing regular, specific maintenance helps you avoid expensive engine repairs.

Key Components and Design Features

Pressure Operation: Remember, the OM457 cooling system runs under pressure, particularly when it’s warm. Hot coolant can cause serious scalds, so I suggest you exercise caution when opening the system.

Component Overview: Key parts of the cooling system are the oil pan, the oil pump (which has a relief valve), and the oil retention valve.

Targeted Cooling: The system cools each critical area individually. For instance, the fuel injector nozzle holder sits inside a special protective sleeve. Coolant fully surrounds this sleeve. It uses an O-ring and a threaded connection to create a tight seal, preventing both coolant and gas leaks.

Cooling System Warning Signs & Immediate Actions

If you notice the coolant or engine oil temperature rising fast, you need to act right away: – Pull over and park the vehicle or equipment in a safe place. – Secure it so it cannot roll away. – Shift the transmission into neutral or uncouple the drive system.

If you ignore these signs, you risk sudden overheating. This can lead to serious cylinder head damage.

Proper Engine Shutdown to Prevent Overheating

After the engine runs at high temperatures (coolant over 90°C) or operates at full power, let the engine idle for about two minutes before you turn it off. – I find this brief cooling period helps prevent thermal stress. It keeps the cylinder head safe from cracking.

BlueTec® System & Exhaust Cooling

The BlueTec® system handles exhaust gas aftertreatment. After shutdown, it flushes the exhaust system using fresh air.

This flushing might happen more than once. It depends on how hard the engine was working before you stopped it.

You might hear a hissing sound when this system activates. This noise is normal; it’s just the air valve working.

Routine Maintenance Checks

When you work on the OM457 cooling system, I recommend you always perform these checks: – Check for fuel leaks. Ensure the fuel intake pressure is correct. – Confirm all seals and connections are tight. Pay attention to the nozzle sleeve O-rings to stop coolant or gas loss. – Examine the high-temperature, wear-resistant valve seat rings with care. These rings are inserted deep into the cylinder head using a cold method. They are very important for managing engine heat.

Performing regular inspections and acting fast on any warning signs will greatly lower the risk of overheating and cylinder head cracking in your OM457 engine.

Warning Signs of Cylinder Head Problems

From my experience, noticing cylinder head problems in OM457 engines soon is vital. It helps you avoid serious damage and expensive repairs. Here are the common symptoms I suggest you watch for:

Engine Overheating and Temperature-Related Warnings

Sudden Engine Overheating: See the temperature gauge rise during normal driving? That’s a big warning sign. You might see the coolant temperature warning light (?) flash on the instrument panel. Ignoring this can lead to cylinder head cracks fast.

Warning Lights and Sounds: Does the oil pressure warning light (5) show up? Do you hear a warning buzzer? Does the engine stop indicator (red) turn on (maybe with a sound)? I recommend you check these issues right away.

Unusual Exhaust Smoke

White Exhaust Smoke: Seeing constant white smoke from the exhaust? Does it smell sweet? This often means that coolant is leaking into the combustion chamber. A cracked cylinder head could be the cause.

Heavy Exhaust Smoke: If you see more heavy or thick exhaust smoke, it points to internal engine problems. These could connect to the cylinder head.

Coolant and Oil Abnormalities

Unexplained Coolant Loss: Do you add coolant often but see no leaks? An internal leak, often from a cracked head, is a strong possibility.

Oil Contamination: If the engine oil looks milky or foamy, coolant is mixing with it. This harms lubrication and can badly damage the engine.

Oil Leakage: A lot of oil leaking into the engine compartment is a serious warning. I’ve seen cases where the engine area was “soaked with oil” because of cylinder head issues.

Declining Engine Performance

Performance Issues: Pay attention to rough idling or sudden misfires. Notice less power or poor fuel efficiency? A cracked head can cause compression loss, leading to these problems. You might also see the engine speed or power drop even if you hold the accelerator steady.

Starting Difficulties: The engine might start clicking but not turn over. Or, it might turn just a few times and then stop.

Visual Clues and Inspection Findings

Physical Damage: When you inspect visually, particularly if you remove the cylinder head, look for cracks or damage on the surface. In bad cases, you might find erosion craters on cylinders. This problem looks like issues found in OM617 diesel engines.

Based on my experience, spotting these warning signs quickly can save your OM457 engine from major damage. It helps keep your engine running reliably and efficiently.

FAQs:

1. How often should I inspect my OM457 cylinder head?

Inspect the cylinder head during major services (every 20,000–40,000 km) or if you notice symptoms like overheating, coolant loss, or misfires. Check bolts and gaskets during these intervals.

2. What causes OM457 cylinder head cracks most frequently?

Overheating due to thermal stress, improper maintenance, or using incorrect gaskets is the leading cause. High-stress operating conditions and engine modifications also increase risk.

3. Can I reuse gaskets when reassembling the cylinder head?

No, always use new gaskets and O-rings to ensure a proper seal. Reusing old seals risks leaks, overheating, and cracks.

4. How do I know if my OM457 engine is overheating?

Look for a rising temperature gauge, a flashing coolant warning light, or unusual exhaust smoke. Immediate action (e.g., pulling over) is critical to prevent damage.

5. What’s the role of the cooling system in preventing cylinder head cracks?

The cooling system regulates engine temperature, reducing thermal stress on the cylinder head. Regular checks of coolant levels, seals, and components are essential.

6. Are aftermarket modifications safe for the OM457 engine?

Modifications like twin-turbo setups or emission deletions can increase combustion stress, raising the risk of cracks. Stick to OEM specifications for optimal performance.

7. Where can I find the OM457 maintenance manual?

Contact your Mercedes-Benz dealer or refer to the official OM457 service manual available through authorized service centers.