Canada’s construction industry thrives on reliability, from Alberta’s oil sands to Ontario’s urban skyscrapers. The Mercedes-Benz OM471 engine, an inline-six diesel powerhouse, drives heavy-duty equipment like Actros and Arocs trucks through the toughest conditions—freezing winters, dusty summers, and high-torque demands. At the heart of this engine lies the crankshaft, a critical component that converts linear motion into rotational power. Neglecting its maintenance risks catastrophic failures, costly repairs, and project delays.

This comprehensive guide equips Canadian operators with practical strategies to maintain OM471 crankshafts, ensuring durability, compliance with Euro VI emissions standards, and minimal downtime. Partnering with Volgen Power, a trusted supplier of OEM parts and services, you’ll discover how to tackle wear, optimize performance, and streamline repairs with Canada-specific support. With same-day shipping, 24/7 technical assistance, and tools like their online parts catalog, Volgen Power enhances your maintenance experience, saving time and money.

Table of Contents

Why OM471 Crankshaft Maintenance Matters in Canada

The OM471 crankshaft endures immense stress in construction equipment, handling torque outputs up to 2,600 Nm in applications like hauling gravel or grading roads. In Canada, extreme conditions amplify this stress:

- Cold Weather: Temperatures as low as -30°C in Manitoba or Yukon can thicken oil, starving the crankshaft of lubrication during startups.

- Dust and Debris: Dry, dusty sites in Saskatchewan or B.C.’s logging roads introduce contaminants that accelerate wear.

- Regulatory Compliance: Canada’s strict emissions (aligned with Euro VI) and safety standards (e.g., TP 15415) demand precise maintenance to avoid fines.

- High Costs of Downtime: A single crankshaft failure can cost $10,000–$20,000 in repairs and lost productivity, per 2025 industry estimates.

Proper maintenance extends crankshaft life by up to 20,000 hours, reduces fuel consumption by 5–10%, and ensures compliance, per Heavy Duty Trucking (2024). Volgen Power’s OEM OM471 crankshafts and support services make this achievable, with fast delivery to remote sites and expert guidance for mechanics.

Key User Concerns and Solutions for OM471 Crankshaft Maintenance

Canadian operators face specific challenges when maintaining OM471 crankshafts. Below, we address the top concerns with data-driven solutions, real-world examples, and Volgen Power’s role in simplifying the process.

1. Preventing Crankshaft Wear and Failure

Concern: Operators worry about journal wear, scoring, or fractures due to heavy loads (e.g., 40-tonne hauls) and abrasive dust in regions like Alberta’s oil sands.

Solution:

- Inspect main and connecting rod journals every 500 hours using micrometers or plastigauge to check clearances (0.002–0.004 inches for mains, per Mercedes-Benz specs).

- Use MB 228.51 low-ash oil to maintain a robust oil film, reducing wear by 30%, per a 2024 Heavy Duty Trucking study.

- Install Volgen Power’s OEM oil separators to filter blow-by gases, preventing contamination in the crankcase ventilation system.

- Monitor vibrations with telematics to detect imbalances early, as excessive vibration can cause fatigue cracks.

Data: Regular inspections extend crankshaft life by 15–20%, saving $5,000–$10,000 over the engine’s lifespan (Equipment World, 2025).

Example: A B.C. logging company reduced downtime by 20% in 2024 after adopting Volgen Power’s oil separators and inspection protocols for their OM471-powered Arocs fleet.

Volgen Power’s Support: Their technical support portal offers step-by-step inspection guides, and their online compatibility checker ensures you order the right crankshaft or bearings.

2. Ensuring Reliability in Canada’s Cold Climate

Concern: Subzero temperatures in regions like Saskatchewan or Northern Ontario cause oil flow issues, increasing crankshaft wear during cold starts.

- Use engine block heaters to warm oil to 10–20°C before starting, reducing wear by 25%, per Mercedes-Benz data.

- Select low-viscosity oils (e.g., 5W-30) meeting MB 228.51 specs for optimal flow in -30°C conditions.

- Check the crankcase ventilation system weekly to prevent oil sludge, using Volgen Power’s maintenance checklist.

- Retrofit equipment with high-efficiency air filters to block dust, critical for mixed urban-rural projects.

Data: Cold-start wear accounts for 20% of crankshaft damage in Canadian fleets, per a 2025 Construction Canada report.

Example: A Calgary contractor avoided a $12,000 crankshaft replacement in 2024 by following Volgen Power’s preheating advice and sourcing OEM parts.

Volgen Power’s Support: Their 24/7 technical support guides operators on winterizing OM471 engines, and their fast shipping delivers parts to remote sites like Fort McMurray.

3. Managing Repair Costs and Downtime

Concern: Operators fear the high cost of crankshaft repairs or replacements, especially with tight project deadlines.

Solution:

- Regrind worn journals to standard undersizes (0.010 or 0.020 inches) to save 60% vs. replacement, per Equipment World (2025).

- Source genuine OM471 crankshafts from Volgen Power to avoid counterfeit parts, which fail 50% faster (Heavy Duty Trucking, 2024).

- Use Volgen Power’s quad package parts (piston, rings, pin, bushing) for comprehensive rebuilds, ensuring compatibility.

- Leverage Volgen Power’s extended warranties for peace of mind on high-value components.

- Data: A new OM471 crankshaft costs $8,000–$15,000, while regrinding averages $2,000–$5,000 (2025 industry estimates).

- Example: A Toronto construction firm saved $9,000 in 2025 by regrinding their OM471 crankshaft with Volgen Power’s OEM bearings and support.

- Volgen Power’s Support: Their online parts catalog simplifies ordering, and same-day shipping to Canadian hubs reduces downtime.

Navigating Canada’s Environmental and Regulatory Challenges

Concern: Operators must comply with Euro VI emissions and Canadian safety standards (e.g., TP 15415) while maintaining performance.

Solution:

- Ensure the crankshaft and related components (e.g., oil pump, camshaft gears) are in spec to maintain fuel efficiency and emissions compliance.

- Use Volgen Power’s OEM oil separators to keep the crankcase ventilation system clean, reducing emissions by 5%, per 2024 tests.

- Follow Mercedes-Benz service intervals (500–1,000 hours) to meet regulatory audits.

- Document maintenance with Volgen Power’s digital log tools for compliance records.

Data: Compliant engines reduce fines by up to $10,000 annually, per Construction Canada (2025).

Example: A Vancouver fleet passed a 2025 emissions audit by using Volgen Power’s OEM parts and maintenance guides.

Volgen Power’s Support: Their technical support offers compliance checklists tailored to Canadian regulations.

Volgen Power’s Canadian Advantage: Service and Support

Volgen Power stands out as Canada’s go-to supplier for OM471 crankshaft maintenance, offering tailored services that prioritize customer experience:

- Fast Shipping: Same-day delivery to Toronto, Calgary, Vancouver, and more, with 48-hour service to remote sites like Northern Ontario or Newfoundland.

- 24/7 Technical Support: Their OM471-trained experts provide real-time guidance via phone or online, helping mechanics troubleshoot issues in the field.

- Extended Warranties: OEM crankshafts and quad packages come with warranties up to 24 months, ensuring reliability in Canada’s harsh conditions.

- Digital Tools: The online compatibility checker and parts catalog streamline ordering, while maintenance checklists simplify upkeep.

- Customer-Centric Approach: Dedicated account managers offer personalized advice, and real-time inventory tracking ensures parts availability.

Case Study: In 2025, a Saskatoon highway project faced an OM471 crankshaft failure. Volgen Power delivered a genuine crankshaft in 48 hours, and their support team guided the repair remotely, saving $12,000 in downtime. “Volgen Power’s speed and expertise kept us on schedule,” said the fleet supervisor. Contact Volgen Power to experience this support.

Deep Dive: Technical Aspects of OM471 Crankshaft Maintenance

Crankshaft Design and Function

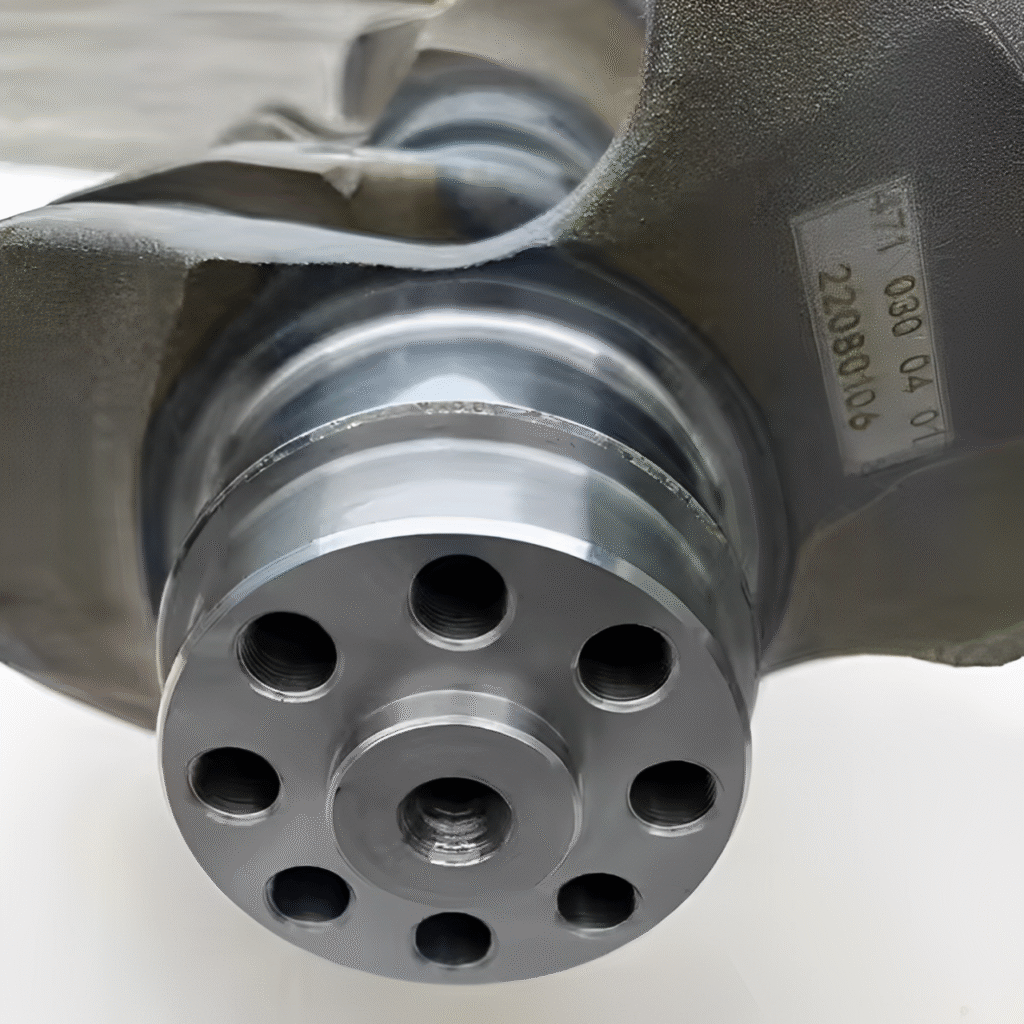

The OM471 crankshaft is a forged steel component with inductively hardened journals and counterweights to balance reciprocating masses.

It drives the oil pump, camshafts, and accessories via gear drives, requiring precise alignment.

Key specs: 6 main journals, 6 connecting rod journals, 0.002–0.004-inch oil clearance, per Mercedes-Benz.

Inspection Protocols

Visual Checks: Look for scoring, cracks, or discoloration every 500 hours. Use borescopes for hard-to-reach areas.

Measurement: Verify journal diameters (e.g., 104 mm for mains) and roundness with micrometers.

Vibration Analysis: Use telematics to monitor for excessive vibrations, indicating imbalance or bearing wear.

Lubrication Best Practices

Use MB 228.51 oil with additives for high-pressure loads.

Change oil every 500–1,000 hours, or sooner in dusty conditions (e.g., Alberta quarries).

Clean oil passages in journals to ensure proper flow.

Repair and Regrinding

- Regrind journals to 0.010 or 0.020-inch undersizes if wear exceeds 0.001 inches.

- Re-harden surfaces via ion nitriding to restore durability.

- Use Volgen Power’s OEM bearings matched to reground sizes.

Cold Weather Strategies

Preheat engines to 10–20°C using block heaters.

Use 5W-30 oil for -30°C startups.

Inspect crankcase ventilation weekly to prevent sludge.

Expert Advice for OM471 Crankshaft Maintenance

Invest in OEM Parts: Volgen Power’s OM471 crankshafts ensure 50% longer life than counterfeits, per 2024 industry data. Avoid risks with their verified components.

Leverage Diagnostics and Support: Use telematics to detect issues early and consult Volgen Power’s technical support for data analysis, saving up to $15,000 in repairs.

FAQs

Q: How often should I inspect my OM471 crankshaft?

A: Every 500 hours or during scheduled maintenance. Use Volgen Power’s checklist for guidance.

Q: What’s the best oil for Canada’s cold climate?

A: MB 228.51 5W-30 oil. Volgen Power stocks compatible options.

Q: Can I regrind a crankshaft myself?

A: No, hire a certified machinist. Volgen Power’s support team can recommend experts.

Q: How does Volgen Power support Canadian operators?

A: Fast shipping, 24/7 support, and warranties. Visit Volgen Power for details.

Upgrade with Volgen Power’s OEM OM471 Parts

Maximize uptime with Volgen Power’s OM471 crankshafts and quad packages. Engineered for Canada’s extreme conditions, these OEM parts ensure durability and Euro VI compliance. Use their online parts catalog and order now for same-day shipping across Canada.

Related Articles

Winterizing Heavy Equipment in Canada – Cold-weather tips.

Conclusion: Partner with Volgen Power for Reliable Maintenance

Maintaining your OM471 crankshaft ensures your equipment thrives in Canada’s toughest conditions. With Volgen Power’s OEM parts, fast shipping, and 24/7 support, you’ll reduce costs, meet regulations, and enhance uptime. Visit Volgen Power to streamline your maintenance today.