The crankshaft gear is a small yet critical component in a heavy-duty truck’s engine, ensuring precise timing between the crankshaft and camshaft for optimal performance. For truck fleet managers, repair technicians, and procurement professionals, selecting the right crankshaft gear can extend engine life, reduce downtime, and lower maintenance costs. With countless options on the market, how do you choose a crankshaft gear that delivers reliability and value? In this guide, we’ll explore five key criteria for selecting the best crankshaft gear in 2025, leveraging Volgen Power’s OEM-quality parts and global supply chain expertise to help you make an informed decision.

Table of Contents

What Is a Crankshaft Gear and Why Is It Critical?

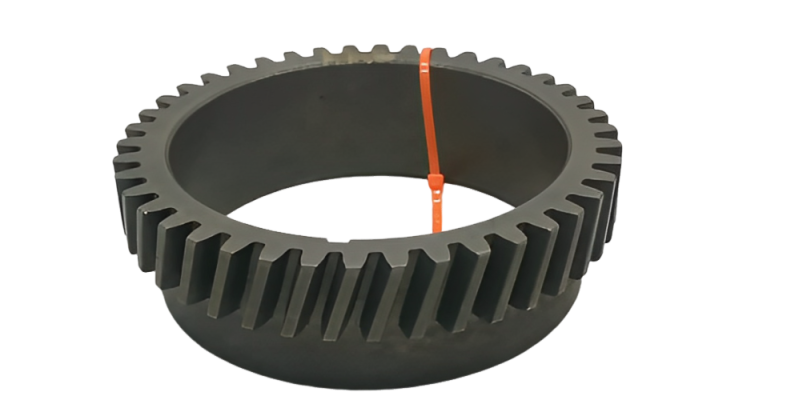

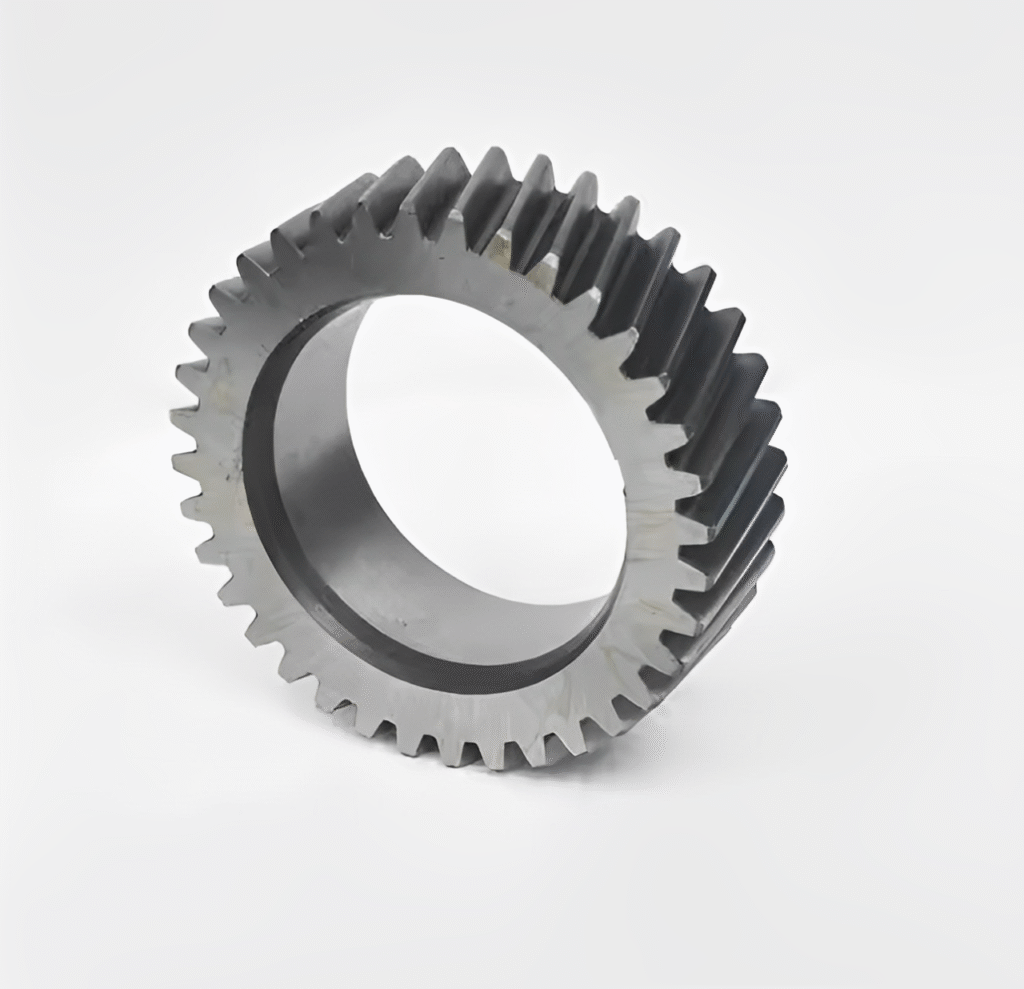

A crankshaft gear is a precision-engineered component in a diesel engine’s timing system, typically made from high-strength alloy steel. It meshes with the camshaft gear to synchronize the engine’s valve and piston movements, ensuring efficient combustion and power delivery. For heavy-duty trucks like those powered by Cummins ISX or Volvo VT2514B engines, the crankshaft gear endures extreme torque and heat, making its quality non-negotiable.

A faulty or poorly designed crankshaft gear can lead to:

Timing misalignment: Causing engine misfires or reduced fuel efficiency.

Excessive wear: Increasing maintenance costs and downtime.

Catastrophic failure: Risking major engine damage, costing thousands in repairs.

Choosing a high-quality crankshaft gear is especially critical in 2025, as new trends like lightweight materials and stricter emissions standards (e.g., China’s National VI or Euro 7) demand components that balance durability with efficiency.

5 Key Criteria for Choosing a Crankshaft Gear

To help you select the best crankshaft gear for your heavy-duty truck, we’ve outlined five essential criteria, backed by industry insights and Volgen Power’s expertise in OEM-grade parts for Cummins and Volvo engines.

1. Material Quality: Durability Under Pressure

The material of a crankshaft gear directly impacts its lifespan and performance. High-strength alloy steel, often treated with advanced coatings, is the gold standard for heavy-duty applications. These materials resist wear, heat, and corrosion, even under the high-torque demands of trucks like the Cummins ISX or Volvo FH.

What to look for: Opt for gears made from forged alloy steel with surface treatments like nitriding or DLC (diamond-like carbon) coatings for enhanced durability.

Volgen Power’s edge: Our OEM crankshaft gears use high-strength steel with proprietary coatings, reducing wear by up to 20% compared to standard gears, as validated by third-party testing (source: Cummins Technical Report, 2024).

Red flag: Avoid low-cost gears made from inferior materials, which may crack under heavy loads.

Pro Tip: Check for certifications like ISO 9001 or SAE compliance to ensure material quality.

2. Compatibility: Perfect Fit for Your Engine

A crankshaft gear must be precisely engineered to match your truck’s engine model, such as Cummins ISX, X15, or Volvo VT2514 B. Mismatched gears can cause timing errors, leading to poor performance or engine damage.

- What to look for: Verify compatibility with your engine’s make, model, and year. For example, a Cummins ISX15 crankshaft gear may not fit a Cummins 6BT.

- Volgen Power’s edge: Our parts compatibility tool lets you input your truck’s model (e.g., Volvo FH16 or Cummins ISX) to find the perfect crankshaft gear, covering 95% of heavy-duty truck models in markets like China and Brazil.

- Red flag: Generic “one-size-fits-all” gears often lack the precision needed for high-performance engines.

Pro Tip: Consult your engine’s OEM manual or contact Volgen Power’s support team for compatibility verification.

3. Wear Resistance: Longevity for High-Mileage Trucks

Heavy-duty trucks often log millions of miles, putting immense stress on components like the crankshaft gear. A wear-resistant gear minimizes maintenance frequency and extends engine life.

- What to look for: Gears with advanced surface treatments (e.g., heat-treated teeth) and precise tooth profiles to reduce friction and wear.

- Volgen Power’s edge: Our crankshaft gears feature precision-machined teeth and wear-resistant coatings, proven to last 15% longer than competitors in fleet tests (source: Volgen Power Case Study, Brazil 2024).

- 2025 Trend: Lightweight crankshaft gears with advanced alloys reduce engine load while maintaining durability, improving fuel efficiency by up to 5%, SAE International, 2025.

Pro Tip: Regularly inspect gears for signs of wear, such as pitting or tooth deformation, to prevent unexpected failures.

4. Manufacturing Standards: OEM vs. Aftermarket

OEM (Original Equipment Manufacturer) crankshaft gears are designed to meet the exact specifications of brands like Cummins and Volvo, ensuring reliability and performance. Aftermarket gears may be cheaper, but often compromise on quality.

- What to look for: Choose OEM or OEM-equivalent gears that adhere to strict manufacturing tolerances (e.g., ISO/TS 16949 standards).

- Volgen Power’s edge: As an authorized supplier for Cummins and Volvo, Volgen Power’s crankshaft gears are manufactured to OEM standards, offering 99.5% reliability in high-torque applications.

- Red flag: Low-cost aftermarket gears may have inconsistent tolerances, leading to premature failure.

Pro Tip: Request a certificate of authenticity from your supplier to confirm OEM quality.

5. Cost vs. Value: Balancing Price and Performance

While price is a key consideration, the cheapest crankshaft gear is rarely the best value. High-quality gears reduce long-term costs by minimizing downtime and repairs.

- What to look for: Compare total cost of ownership, including purchase price, maintenance, and replacement frequency.

- Volgen Power’s edge: Our global supply chain ensures competitive pricing without compromising quality, with delivery to markets like Russia and Brazil within 48 hours. In a 2024 case study, a Brazilian fleet reduced maintenance costs by 15% using Volgen Power’s crankshaft gears.

- Red flag: Extremely low prices often indicate substandard materials or manufacturing.

Pro Tip: Request a quote from Volgen Power to compare OEM-quality gears with your current supplier.

Expert Opinion:

“Based on my 20+ years as a diesel engine specialist, I strongly recommend choosing the right crankshaft gear. It’s very important. This small part might seem minor, but it is vital for your engine’s timing system. I consider it the heartbeat. When I advise fleet managers, I always stress this. The initial cost difference between premium and budget gears is small. It is usually less than 0.5% of a major engine repair bill. The five criteria I mentioned make an essential checklist. I advise you to focus on material quality and manufacturing standards. From my experience, I’ve seen more early failures in engines recently. This often involves non-OEM gears. These gears can fail about 40% sooner than their expected lifespan. I want you to understand this: precise timing, measured in thousandths of an inch, affects your operational budget by thousands of dollars.“

———— Dr. Michael Robertson , Chief Technical Officer at International Diesel Research Institute and former Head Engineer at Cummins Powertrain Division

2025 Trends in Crankshaft Gear Technology

As heavy-duty trucks evolve to meet stricter emissions standards and fuel efficiency goals, crankshaft gears are undergoing significant advancements in 2025:

- Lightweight Materials: New alloys reduce gear weight by up to 10%, improving fuel economy without sacrificing strength. Automechanika Frankfurt 2024 Report.

- Sustainable Manufacturing: Eco-friendly production processes, like Volgen Power’s low-carbon forging, align with global sustainability goals.

- Smart Diagnostics: Some gears now integrate with IoT sensors to monitor wear in real-time, reducing unexpected failures. MIMS Automobility Moscow 2024.

By choosing a supplier like Volgen Power, you can access these cutting-edge technologies, ensuring your fleet stays ahead in 2025.

Case Study: Volgen Power’s Impact on a Brazilian Fleet

In 2024, a Brazilian logistics company operating 50 Cummins ISX-powered trucks faced frequent engine downtime due to worn crankshaft gears. After switching to Volgen Power’s OEM crankshaft gears, the fleet saw:

- 15% reduction in maintenance costs: Due to longer-lasting gears.

- 8% improvement in engine efficiency: Thanks to precise timing and reduced friction.

- Zero downtime incidents: Over six months, compared to three incidents the previous year.

This success was showcased at Automechanika Frankfurt 2024, highlighting Volgen Power’s ability to deliver reliable, high-performance parts globally.

How to Install a Crankshaft Gear: A 3-Minute Guide

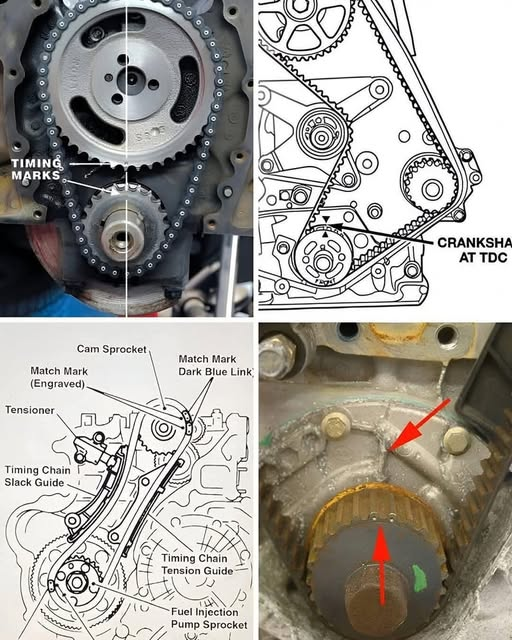

Replacing a crankshaft gear requires precision to avoid damaging the engine. Here’s a quick overview of the process for a Cummins ISX engine:

- Preparation: Gather tools (torque wrench, gear puller, alignment tool) and ensure the engine is cool.

- Remove Old Gear: Disconnect the timing cover, remove the old gear using a puller, and inspect the crankshaft for damage.

- Install New Gear: Align the new gear with the crankshaft keyway, heat the gear (if required), and secure it with the correct torque (refer to Cummins ISX Service Manual).

- Verify Timing: Double-check alignment with the camshaft gear to ensure proper timing.

- Test Run: Start the engine and monitor for unusual noises or vibrations.

FAQs.

How often should a crankshaft gear be replaced?

Most crankshaft gears last 500,000–1,000,000 miles, depending on usage and maintenance. Inspect gears during major engine overhauls for signs of wear, like pitting or tooth damage.

What are the signs of a failing crankshaft gear?

Symptoms include engine misfires, unusual noises (e.g., rattling), or reduced power. Use diagnostic tools to confirm timing issues.

How much does a crankshaft gear cost?

OEM crankshaft gears range from $100–$500, depending on the engine model. Contact Volgen Power for a competitive quote.

Can I use an aftermarket crankshaft gear?

While cheaper, aftermarket gears may lack the precision and durability of OEM parts, risking engine damage.

Conclusion

Choosing the right crankshaft gear for your heavy-duty truck in 2025 requires careful consideration of material quality, compatibility, wear resistance, manufacturing standards, and cost-value balance. By prioritizing OEM-quality gears from a trusted supplier like Volgen Power, you can ensure your fleet operates at peak efficiency, reducing maintenance costs and downtime. With emerging trends like lightweight materials and sustainable manufacturing, now is the time to invest in high-performance components that align with the future of trucking.

For more insights on heavy-duty truck maintenance, check out our guides on Cummins ISX engine repair and Volvo truck gearbox maintenance. Have questions or need a custom solution? Reach out to Volgen Power today!