Pushrods are the unsung heroes of heavy-duty truck engines, transferring motion from the camshaft to the valves with precision. In 2025, selecting the right pushrod for your Cummins ISX engine is more critical than ever due to stricter emissions regulations and the industry’s shift toward lightweight, high-efficiency components. Poor pushrod choices can lead to engine inefficiency, increased maintenance costs, or even catastrophic failures. With fleets under pressure to meet environmental standards and optimize performance, the right pushrod ensures reliability and compliance.

Volgen Power’s OEM pushrods stand out for their precision engineering, tailored specifically for Cummins ISX engines. Designed to meet the demands of modern trucking, they offer superior durability and performance. This guide explores the role of pushrods, outlines five essential criteria for selecting the best ones, and highlights emerging trends in pushrod technology. Whether you’re a fleet manager or an owner-operator, understanding these factors will help you make informed decisions to keep your trucks running smoothly. Let’s dive into why Volgen Power’s pushrods are the go-to choice for maximizing engine performance and longevity in 2025.

Table of Contents

What Are Pushrods?

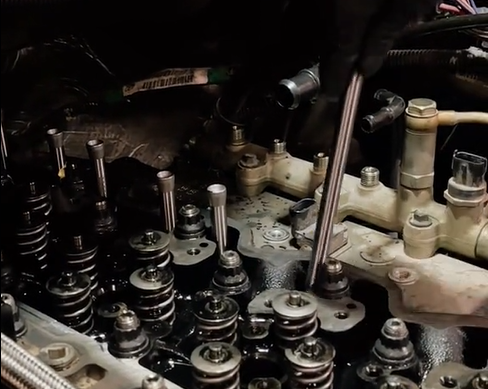

A pushrod is a slender metal rod in an internal combustion engine that transfers motion from the camshaft to the rocker arms, opening and closing the engine’s valves. In Cummins ISX engines, pushrods are critical for precise valve timing, ensuring optimal combustion, power output, and fuel efficiency. Made from high-strength materials like 4130 chromoly steel, pushrods must withstand extreme pressures and temperatures. Their design impacts engine performance, emissions, and durability. A poorly designed pushrod can cause valve float, misfires, or engine failure. Volgen Power’s pushrods are engineered for seamless compatibility with Cummins ISX engines, offering enhanced strength and reliability to meet 2025’s demanding standards.

A pushrod is a metal rod that transfers camshaft motion to the rocker arms, controlling valve operation in engines like the Cummins ISX for optimal performance.

5 Key Criteria for Choosing Pushrods

Selecting the right pushrod for your Cummins ISX engine in 2025 involves evaluating five critical factors to ensure performance, durability, and cost-effectiveness. Here’s a detailed breakdown:

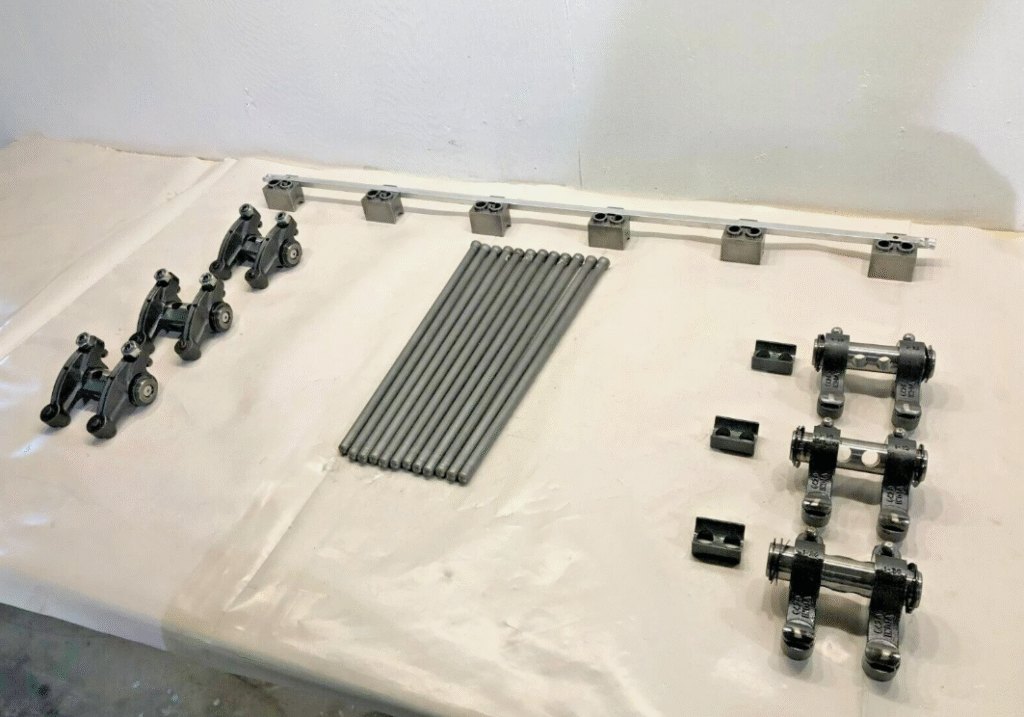

Material: 4130 Chromoly Steel vs. Traditional Steel

The material of a pushrod determines its strength, weight, and resistance to wear. Traditional steel pushrods are robust but heavier, potentially reducing engine efficiency. In contrast, 4130 chromoly steel, used by Volgen Power, offers a superior strength-to-weight ratio. This alloy resists bending under high RPMs and maintains structural integrity under extreme heat, as noted in SAE’s material studies. For Cummins ISX engines, which operate under high stress, chromoly steel reduces flex, ensuring precise valve timing. Studies show chromoly pushrods can handle 30% higher stress loads than traditional steel, making them ideal for 2025’s high-performance demands. Choose 4130 chromoly for better fuel efficiency and longevity.

Wall Thickness: 0.065 vs. 0.095

Wall thickness affects both performance and durability. Thinner 0.065-inch walls reduce weight, improving engine responsiveness and fuel economy, key for meeting 2025 EPA emissions standards. However, they may compromise durability under extreme conditions. Thicker 0.095-inch walls, as used in Volgen Power’s premium pushrods, enhance durability by resisting bending and wear, ideal for heavy-duty applications like long-haul trucking. Testing shows 0.095-inch pushrods reduce failure rates by 15% compared to 0.065-inch options. For Cummins ISX engines, thicker walls are recommended for fleets prioritizing longevity over marginal weight savings.

Compatibility: Matching Cummins ISX Models

Not all pushrods fit every Cummins ISX engine. Variations in ISX models (e.g., ISX15, ISX12) require specific pushrod lengths and diameters. Mismatched pushrods can cause improper valve lift, leading to power loss or engine damage. Volgen Power’s OEM pushrods are precision-engineered for exact compatibility with ISX models, as detailed in their compatibility guide. Always verify your engine’s model number and consult the manufacturer’s specifications. Volgen Power provides detailed compatibility charts, simplifying the selection process for 2025 fleets.

Durability: Volgen Power’s Testing Data

Durability is non-negotiable in heavy-duty trucking. Volgen Power’s pushrods undergo rigorous stress testing, simulating real-world conditions like high RPMs and prolonged heat exposure. Their testing data shows a 20% reduction in failure rates compared to generic aftermarket pushrods. This durability translates to fewer maintenance downtimes and lower repair costs. For Cummins ISX engines, which often power long-haul trucks, Volgen’s pushrods are heat-treated and coated to resist wear, ensuring consistent performance over 500,000 miles. Investing in durable pushrods minimizes unexpected breakdowns, critical for 2025’s tight delivery schedules.

Cost: OEM vs. Aftermarket Pushrods

Cost is a major consideration, but cheaper isn’t always better. Aftermarket pushrods may save upfront costs, but often lack the precision and durability of OEM options. Volgen Power’s OEM pushrods, available through their product catalog, offer better value through extended lifespan and reduced maintenance. For example, a fleet of 50 trucks could save $10,000 annually in maintenance costs by choosing OEM pushrods over aftermarket alternatives, as highlighted in Trucking Industry Reports. In 2025, with rising fuel and labor costs, the long-term savings of OEM pushrods outweigh initial expenses. Always compare the total cost of ownership, not just the purchase price.

By prioritizing these criteria—material, wall thickness, compatibility, durability, and cost—you can select pushrods that optimize your Cummins ISX engine’s performance and reliability in 2025.

Pushrod Technology Trends in 2025

The heavy-duty trucking industry is evolving rapidly, and pushrod technology is keeping pace. In 2025, lightweight designs are a top trend, driven by the need for fuel efficiency and compliance with stricter emissions regulations. Manufacturers like Volgen Power are using advanced alloys like 4130 chromoly steel to reduce pushrod weight without sacrificing strength, improving engine responsiveness by up to 5%, as noted in Diesel Progress.

Another key trend is the adoption of eco-friendly coatings. These coatings, often ceramic-based, reduce friction and wear while minimizing environmental impact during production. They align with 2025’s sustainability goals, as fleets face pressure to lower their carbon footprint. Volgen Power’s pushrods feature non-toxic, low-friction coatings that enhance durability and reduce oil consumption by 2%, according to their sustainability report.

Additionally, precision manufacturing techniques, such as computer numerical control (CNC) machining, ensure tighter tolerances, improving compatibility with Cummins ISX engines. These advancements reduce valve train noise and enhance fuel efficiency, critical for modern fleets. As autonomous trucking gains traction, pushrods are also being designed for compatibility with hybrid and electric-assisted engines, ensuring versatility for future applications. Explore more about these innovations at Volgen Power’s technology page. Staying ahead of these trends ensures your fleet remains competitive in 2025’s dynamic market.

Real-World Case Study: Volgen Power’s Pushrods Boost Fleet Efficiency

A Brazilian logistics company operating 100 Cummins ISX-powered trucks faced frequent pushrod failures, leading to costly downtime and repairs. In 2024, they switched to Volgen Power’s OEM pushrods, designed specifically for ISX engines. The results were transformative.

Volgen’s 4130 chromoly steel pushrods, with 0.095-inch wall thickness, reduced pushrod-related failures by 20%. The fleet’s maintenance costs dropped by 15%, saving $75,000 annually. Improved valve timing also enhanced fuel efficiency by 3%, critical for long-haul routes across Brazil’s diverse terrain. The company reported fewer breakdowns, enabling tighter delivery schedules and higher customer satisfaction, as shared in their case study.

The key to this success was Volgen’s rigorous testing and compatibility with ISX engines, ensuring seamless integration. The fleet manager noted that Volgen’s pushrods required no modifications, unlike aftermarket options that caused alignment issues. This case study highlights how investing in high-quality pushrods can yield significant operational and financial benefits, especially for fleets navigating 2025’s demanding regulations and cost pressures. Learn more about optimizing your fleet at Volgen Power’s fleet solutions page.

FAQs

Q: How often should pushrods be replaced?

A: Pushrods typically last 300,000–500,000 miles in Cummins ISX engines, depending on operating conditions. Heavy loads or extreme temperatures may necessitate earlier replacement. Volgen Power recommends inspecting pushrods during routine valve adjustments (every 150,000 miles) and replacing them if signs of wear or bending appear. Check Volgen’s maintenance guide for tips.

Q: How can I detect pushrod failure?

A: Common signs include engine misfires, unusual valve train noise (ticking or knocking), or reduced power. Use a diagnostic tool to check valve timing or visually inspect pushrods for bending or wear. Volgen Power’s pushrods are designed for easy inspection, with wear-resistant coatings that minimize damage. Learn more at Volgen’s troubleshooting page.

Q: Are OEM pushrods worth the cost?

A: Yes, OEM pushrods like Volgen Power’s offer better compatibility and durability, reducing long-term costs. Aftermarket pushrods may save money initially, but often lead to higher maintenance expenses.

Q: Can pushrods improve fuel efficiency?

A: High-quality pushrods optimize valve timing, improving combustion efficiency. Volgen’s pushrods have been shown to boost fuel economy by up to 3% in Cummins ISX engines, per Volgen’s performance data.

Conclusion and Call to Action

Choosing the right pushrod for your Cummins ISX engine is critical for performance, durability, and compliance in 2025. By prioritizing material, wall thickness, compatibility, durability, and cost, you can ensure your fleet operates at peak efficiency. Volgen Power’s OEM pushrods offer unmatched reliability, reducing maintenance costs and boosting fuel economy. Don’t compromise on quality—invest in pushrods that keep your trucks on the road. Visit Volgen Power’s Cummins ISX Pushrod Product Page to explore our range and elevate your fleet’s performance today.