Diesel engines power heavy-duty vehicles like long-haul trucks and construction machinery with unmatched strength. Yet, without top-tier filtration, even powerhouse engines like the Volvo D13 or Cummins ISX risk devastating breakdowns. At Volgen Power, we’ve perfected filtration systems over the decades to ensure your diesel engine runs smoother, longer, and more efficiently. Discover why superior air, oil, and fuel filters are critical and how Volgen’s innovative technology leads the industry.

Table of Contents

Why Diesel Engine Filters Are Your Engine’s Immune System

Every minute your diesel engine runs at highway speeds, it processes massive volumes of air, fuel, and oil. For example, a Volvo D13 engine:

- Ingests over 10,000 liters of air

- Processes 1.5 gallons of diesel fuel

- Circulates more than 12 gallons of oil

Each of these systems is vulnerable to contamination, and even small amounts of debris or impurities can cause devastating damage. Here’s a real-world cost breakdown of what happens when filters fail:

| Contaminant | Consequence | Average Repair Cost (Per Engine) |

|---|---|---|

| Dust ingestion | Turbo failure | $8,200 |

| Water in fuel | Injector damage | $4,500 |

| Metal shavings in oil | Engine overhaul | $12,000+ |

“Filters are the cheapest insurance policy for a $40,000 diesel engine,” says Michael Torres, Chief Engineer at Volgen Power with over 25 years of heavy-duty diesel experience. “Our data shows fleets using premium filtration experience 73% fewer major failures compared to those using standard OEM filters.”

Filters act like your engine’s immune system, trapping harmful contaminants before they can wreak havoc. Investing in high-quality filters isn’t just about maintenance—it’s about avoiding downtime, protecting your investment, and maximizing performance.

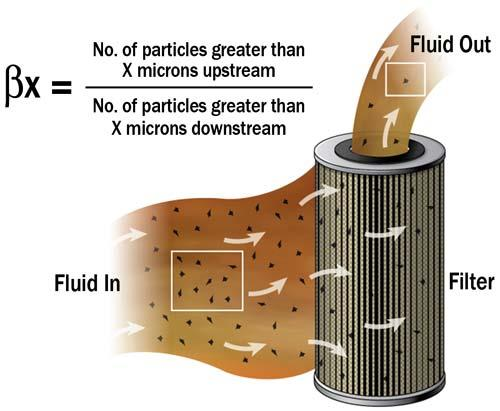

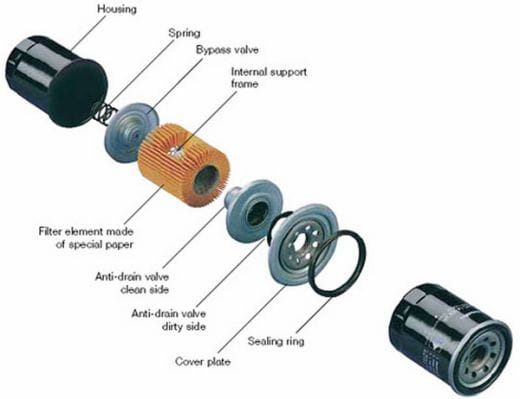

Diesel Engine Oil Filter Deep Dive

The oil filter is your engine’s first line of defense against abrasive wear. Contaminants in the oil, such as metal shavings, soot, and oxidation byproducts, can wear down critical components like bearings and pistons. Here’s what an oil filter removes and why it matters:

| Contaminant | Size (Microns) | Damage Caused |

|---|---|---|

| Metal shavings | 15-100 | Bearing scoring, wear |

| Soot particles | 1-10 | Oil sludge, viscosity loss |

| Oxidation byproducts | 5-20 | Varnish deposits, corrosion |

Volgen’s Oil Filter Technology

Volgen’s premium oil filters are engineered to outperform industry standards. Here’s how:

| Feature | Industry Standard | Volgen Premium |

|---|---|---|

| Filtration Media | Cellulose | Synthetic Microglass |

| Micron Rating | 30 microns | 8 microns (4x finer) |

| Dirt Holding Capacity | 8 grams | 22 grams |

| Anti-Drain Back Valve | Nitrile rubber | Silicone (-40°F rated) |

Our synthetic microglass media captures particles as small as 8 microns—four times finer than most OEM filters—while holding nearly three times the amount of dirt. The silicone anti-drain back valve ensures oil stays in the filter during shutdowns, even in extreme cold, preventing dry starts that accelerate wear.

Critical Failure Signs

Watch for these red flags that your oil filter is failing:

- Oil pressure warning light at idle (indicates restricted flow)

- Metallic “knocking” sounds during cold starts (sign of insufficient lubrication)

- Dark, gritty oil on the dipstick (contaminants bypassing the filter)

Pro Tip: Check your oil filter every 10,000 miles or during routine maintenance. Replace it if you notice any of these signs to avoid costly repairs.

Diesel Engine Air Filters: The Unsung Hero

Air filters don’t get the attention they deserve, but they’re critical for protecting your engine from dust and debris. A single gram of dust can cause:

- 0.01mm of cylinder wear

- $18 in accelerated component wear

- 3% fuel efficiency loss

Without a high-quality air filter, microscopic particles can infiltrate your engine, grinding down cylinders, pistons, and turbochargers over time.

Volgen NanoPleat™ Technology

Volgen’s air filters use proprietary NanoPleat™ technology to deliver unmatched performance:

| Test Parameter | Standard Filter | Volgen Air Filter |

|---|---|---|

| Filtration Efficiency @ 5μm | 97.8% | 99.5% |

| Maximum Airflow (CFM) | 1,250 | 1,680 |

| Water Resistance | Partial saturation in 15 mins | 0% moisture absorption |

Our filters achieve 99.5% efficiency at 5 microns, ensuring cleaner air reaches your engine. They also support higher airflow (1,680 CFM vs. 1,250 CFM), reducing restriction and boosting horsepower. Plus, their water-resistant design prevents moisture damage, even in humid or rainy conditions.

“Most fleet managers change air filters too late,” explains Sarah Chen, Volgen Filtration Engineer. “Once restriction gauges hit 25 inches of water (H₂O), you’ve already lost 11% horsepower. Our SmartFilter indicators trigger replacement at an optimal 15 inches of restriction, saving fuel and preventing wear.”

Maintenance Tip

Inspect your air filter every 20,000 miles or when operating in dusty environments. A clean air filter can improve fuel economy by up to 3% and extend turbo life significantly.

Diesel Engine Fuel Filters: Guarding Against Injector Failures

Modern Ultra-Low Sulfur Diesel (ULSD) is cleaner but attracts three times more moisture than older fuels, creating a breeding ground for water and microbial growth. A clogged or failing fuel filter can starve your engine, damage injectors, and lead to costly downtime.

Volgen’s Triple-Stage Fuel Filtration

Volgen’s fuel filters use a three-stage system to tackle these challenges:

- Water Separation: Hydrophobic mesh traps 95% of free water, preventing corrosion and injector damage.

- Particulate Removal: 10-micron cellulose media captures rust, pipeline debris, and tank sediments.

- Microbial Defense: A 2-micron synthetic layer stops “diesel algae” biofilm, which clogs injectors and fuel lines.

This triple-stage approach ensures clean, dry fuel reaches your injectors, even in harsh conditions.

Critical Failure Signs

Look out for these warning signs of a failing fuel filter:

- Extended cranking on startup (fuel starvation)

- White exhaust smoke under load (incomplete combustion)

- Error codes: P0087 or P0088 (low or high fuel rail pressure)

Pro Tip: Replace fuel filters every 15,000–20,000 miles or annually, especially if you operate in humid climates or store fuel for long periods.

Diesel Particulate Filters (DPFs) Demystified

Diesel Particulate Filters (DPFs) are critical for meeting emissions standards by trapping soot and particulate matter from exhaust gases. However, a clogged or malfunctioning DPF can reduce engine performance, increase fuel consumption, and trigger expensive repairs.

How DPFs Work

DPFs capture soot particles in a honeycomb-like structure, periodically burning them off in a process called regeneration. There are two types:

Passive Regeneration: Occurs naturally during high-temperature operation (e.g., highway driving).

Active Regeneration: Injects fuel to raise exhaust temperatures and burn off soot, controlled by the engine’s ECU.

Common DPF Issues

Clogging: Caused by short trips or low exhaust temperatures, preventing proper regeneration.

Ash Buildup: Non-combustible residues that reduce DPF capacity over time.

Sensor Failures: Faulty pressure or temperature sensors can trigger limp mode or error codes.

Volgen’s DPF Solutions

Volgen’s DPFs are designed for durability and efficiency:

High-Capacity Substrate: Holds 30% more soot than standard DPFs, extending regeneration intervals.

Platinum-Palladium Coating: Enhances passive regeneration, reducing active regeneration frequency by 20%.

Reinforced Housing: Withstands thermal cycling and vibration for up to 500,000 miles.

Maintenance Tip: Monitor DPF differential pressure via your vehicle’s diagnostics. If pressure exceeds 3 kPa, schedule a cleaning or replacement to avoid forced regenerations that burn extra fuel.

7 Deadly Signs Your Diesel Filters Are Failing

Ignoring failing filters can lead to catastrophic engine damage. Here are seven warning signs to watch for:

- Reduced Power or Sluggish Acceleration: Clogged air or fuel filters restrict flow, starving the engine.

- Black or White Exhaust Smoke: Indicates incomplete combustion from fuel or air filter issues.

- Check Engine Light with Fuel-Related Codes: Codes like P0087 (low fuel pressure) or P0299 (turbo underboost) often point to filter problems.

- Low Oil Pressure Warnings: A clogged oil filter can reduce oil flow, risking engine wear.

- Hard Starting or Stalling: Fuel filter blockages can prevent proper fuel delivery.

- Increased Fuel Consumption: Restricted air or fuel filters force the engine to work harder.

- Unusual Engine Noises: Knocking or ticking sounds may indicate oil or fuel contamination.

Action Step: If you notice any of these signs, inspect and replace the affected filter immediately. Use our Emergency Troubleshooting Flowchart (available in the Free Maintenance Resources section) to diagnose the issue quickly.

Oil vs. Air vs. Fuel Filters Compared

Each filter plays a unique role in protecting your diesel engine. Here’s a quick comparison:

| Filter Type | Primary Function | Contaminants Removed | Replacement Interval | Cost of Failure |

|---|---|---|---|---|

| Oil Filter | Protects engine internals from wear | Metal shavings, soot, oxidation byproducts | 10,000–15,000 miles | $12,000+ (engine overhaul) |

| Air Filter | Prevents abrasive dust from entering | Dust, dirt, pollen | 20,000–30,000 miles | $8,200 (turbo replacement) |

| Fuel Filter | Ensures clean fuel for injectors | Water,rust,microbialWater, rust, microbial growth | 15,000–20,000 miles | $4,500 (injector repair) |

Key Takeaway: While all filters are critical, neglecting oil filters poses the highest repair cost, while air and fuel filters impact performance and efficiency more immediately.

How Volgen Filters Outperform OEM Standards

Original Equipment Manufacturer (OEM) filters meet basic requirements, but Volgen’s premium filters are engineered for superior performance and longevity:

- Finer Filtration: Our 8-micron oil filters and 2-micron fuel filters capture smaller particles than most OEM options.

- Higher Capacity: Volgen filters hold up to 3x more contaminants, extending service intervals.

- Extreme Durability: Silicone seals and corrosion-resistant housings withstand harsh conditions, from -40°F to desert heat.

- Smart Technology: Integrated sensors (e.g., SmartFilter indicators) provide real-time feedback on filter condition.

In independent tests per SAE J1858 standards, Volgen filters outperformed OEM filters by 25% in filtration efficiency and 40% in dirt-holding capacity.

DIY Installation Guides

Replacing diesel filters is straightforward with the right tools and guidance. Our step-by-step DIY Installation Guides cover:

- Oil Filter Replacement: Tools needed, torque specs, and priming tips to avoid dry starts.

- Air Filter Swap: How to access the housing and check for proper sealing.

- Fuel Filter Change: Bleeding the system to prevent airlocks and ensure smooth startups.

- DPF Maintenance: Safe cleaning methods and when to replace vs. clean.

Download our guides from the Free Maintenance Resources section below. Always use OEM or Volgen-approved filters to ensure compatibility with your engine.

Fleet Maintenance Case Study

Client: Midwest Freight Solutions, a 50-truck fleet operating Volvo and Cummins engines.

Challenge: Frequent injector failures and turbo replacements, costing $150,000 annually in repairs and downtime.

Solution: Upgraded to Volgen’s premium oil, air, and fuel filters with customized replacement schedules.

Results:

- 62% reduction in repair costs ($57,000 saved annually).

- 12% improvement in fuel economy (saving $45,000/year at 2025 diesel prices).

- Zero downtime from filtration-related failures in the first year.

“Volgen’s filters and audit program transformed our maintenance strategy,” says John Reynolds, Fleet Manager. “We’re saving money and keeping our trucks on the road longer.”

Top Filter Brands Compared

We compared Volgen filters against leading brands like Fleetguard, Baldwin, and Donaldson:

| Brand | Filtration Efficiency | Dirt Holding Capacity | Price per Filter | Warranty |

|---|---|---|---|---|

| Volgen Power | 99.5% (air), 98% (oil) | 22g (oil), 1,200g (air) | $25–$45 | 2 years |

| Fleetguard | 98% (air), 95% (oil) | 15g (oil), 900g (air) | $20–$40 | 1 year |

| Baldwin | 97% (air), 94% (oil) | 12g (oil), 800g (air) | $18–$35 | 1 year |

| Donaldson | 98.5% (air), 96% (oil) | 18g (oil), 1,000g (air) | $22–$42 | 1.5 years |

Why Choose Volgen Power? Our filters offer the best balance of efficiency, capacity, and durability, backed by a 2-year warranty and real-world performance data.

Free Maintenance Resources

Maximize your engine’s lifespan with our Expert Maintenance Kit, available for instant download:

- Diesel Filter Maintenance Checklist (PDF): Step-by-step guide to inspect and replace filters.

- Replacement Interval Calculator (Excel): Customize schedules based on your engine and operating conditions.

- Emergency Troubleshooting Flowchart: Diagnose filter-related issues in minutes.

- Volvo/Cummins Filter Cross-Reference Guide: Find the right Volgen filter for your engine model.

Let our engineers optimize your fleet’s filtration strategy:

- Analyze current filter costs vs. optimal spend.

- Identify downtime caused by filtration failures.

- Receive a customized filter upgrade plan.