The DAF XF105, powered by the 12.9-liter PACCAR MX engine, is a titan in the heavy-duty trucking industry, known for its reliability, fuel efficiency, and Euro 6 compliance. At the core of this engine is the cylinder head—a critical component that governs combustion, airflow, and overall performance. For fleet managers, mechanics, and truck owners, understanding the DAF XF105 cylinder head is essential to maximizing uptime, minimizing costs, and ensuring compliance with modern emissions standards. This comprehensive guide dives deep into the cylinder head’s technical specifications, addresses common user concerns, explores installation and maintenance best practices, and highlights why Volgen Power is your trusted partner for high-quality parts and support. Let’s unlock the full potential of your XF105!

Table of Contents

What Makes the DAF XF105 Cylinder Head Exceptional?

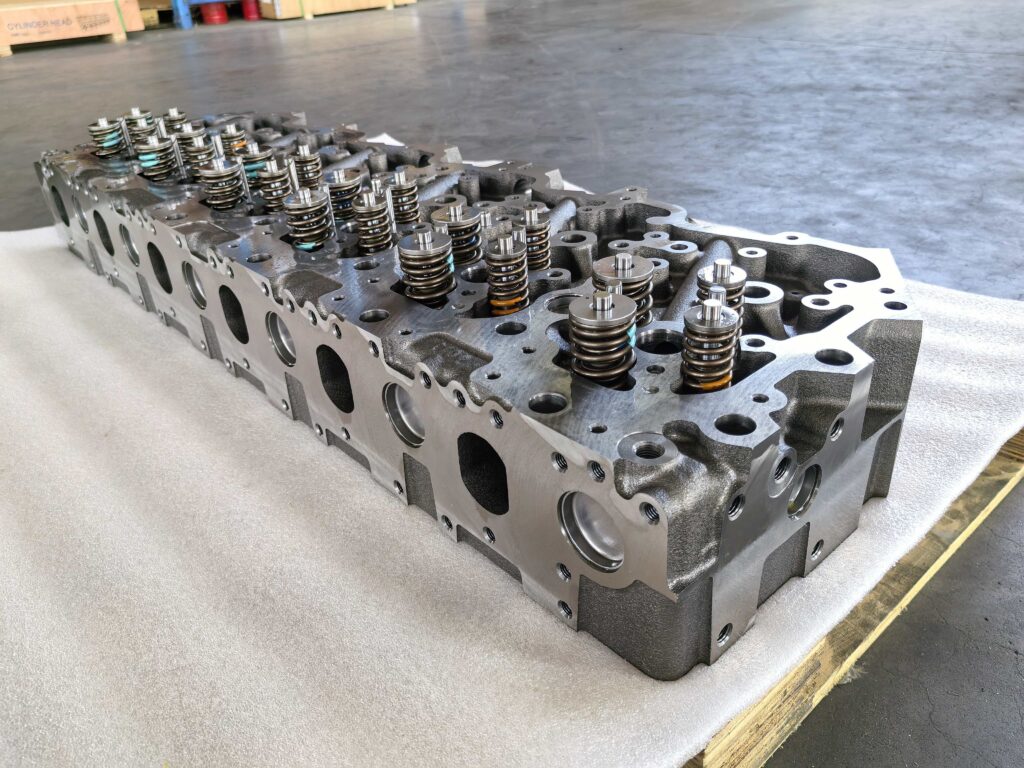

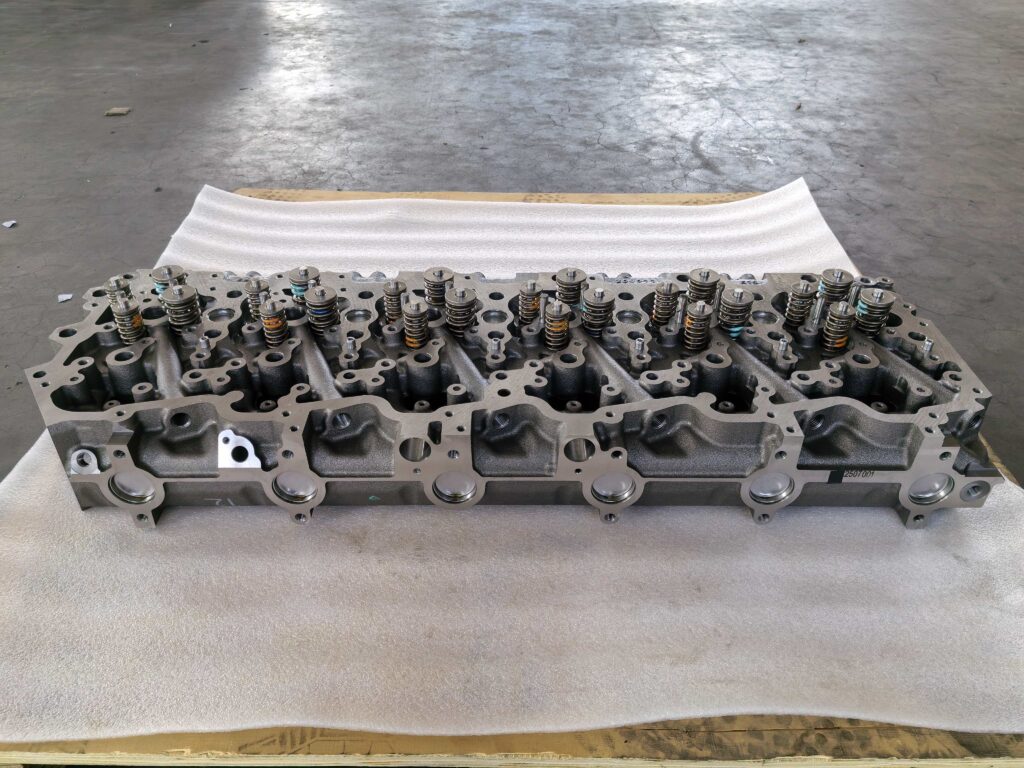

The cylinder head in the DAF XF105’s PACCAR MX engine (available in MX300, MX340, MX375, and MX410 variants, producing 410–510 hp) is a marvel of engineering, designed to balance power, efficiency, and durability. Crafted from high-grade aluminum alloy, it reduces weight while withstanding extreme temperatures and pressures. Its integrated exhaust manifold and turbocharger housing streamline exhaust flow, reducing turbo lag and improving fuel economy (up to 3 km/liter in real-world conditions). The cylinder head’s four-valve-per-cylinder design optimizes airflow, while its common-rail injection system supports pressures up to 2,500 bar, ensuring precise fuel delivery and compliance with Euro 5 and Euro 6 emissions standards.

Technical Specifications

- Material: Aluminum alloy with reinforced valve seats for heat resistance

- Valve Configuration: 24 valves (4 per cylinder) for enhanced airflow

- Compression Ratio: 17.5:1, balancing power and fuel efficiency

- Cooling System: Water-cooled with integrated coolant passages (flow rate: 200 L/min at 2,000 RPM)

- Injector System: Common-rail, 2,500 bar max pressure, Bosch injectors

- Weight: ~85 kg (standalone head), ~120 kg with ancillaries

- Part Numbers: Cylinder head (0683657), gasket kit (1699644), camshaft (1678946)

- Torque Specs: Head bolts torqued to 300 Nm in a crisscross pattern

- Emissions Compliance: Euro 5/6 with SCR and EGR integration

- Thermal Efficiency: Optimized swirl ports improve combustion by 8% compared to Euro 4 designs

The cylinder head’s one-piece design minimizes leak points, and its reinforced camshaft housing withstands high-pressure loads (up to 180 bar peak cylinder pressure). These features make it ideal for demanding applications, such as long-haul routes in high-temperature regions like Australia or the Middle East, where ambient temperatures often exceed 40°C.

Common User Concerns and Data-Driven Solutions

Fleet operators and mechanics frequently encounter issues with the XF105 cylinder head. Below, we address the top concerns with technical solutions, real-world examples, and data to guide you.

1. Overheating and Coolant Loss

Concern: Overheating, often due to cracked cylinder heads or dropped liners, can lead to catastrophic engine failure. A 2013 XF105 in Queensland reported losing 10–12 liters of coolant daily due to a compromised liner seal, costing €4,000 in repairs.

Technical Solution:

- Diagnosis: Perform magnaflux testing to detect micro-cracks and measure liner protrusion (spec: 0.02–0.05 mm). Use a borescope to inspect coolant passages for corrosion.

- Repair: Replace damaged heads with OEM-spec units from Volgen Power. Their 0683657 cylinder head kit includes gaskets and bolts for a complete overhaul. Maintain coolant quality with MB 236.1-compliant fluids (pH: 7.5–8.5) to prevent corrosion.

- Prevention: Pressure-test the cooling system every 80,000 km (spec: 1.5 bar). Monitor coolant temperature (normal: 85–95°C) using onboard diagnostics.

Case Study: Twin View Turf, an Australian fleet operator, avoided recurring coolant issues in their XF105 fleet by adopting Volgen Power’s remanufactured heads and implementing a 90,000 km cooling system flush schedule, saving 12% on annual maintenance costs.

2. NOx Sensor Failures and Limp Mode

Concern: Replacing NOx sensors in Euro 6 XF105 models often triggers fault codes (e.g., P0401 for EGR issues or P0299 for turbo underboost), leading to limp mode and a 50% power reduction.

Technical Solution:

- Diagnosis: Use DAF’s DAVIE diagnostic tool to check sensor output (normal: 0–500 ppm NOx) and wiring harness resistance (<1 ohm). Verify EGR valve functionality (opening: 80–100% at 1,500 RPM).

- Repair: Recalibrate the ECU post-replacement using DMCI software (version 2.3 or later). Volgen Power offers remote diagnostic support and access to DAF service manuals for precise troubleshooting.

- Prevention: Clean EGR and SCR systems every 120,000 km to prevent soot buildup. Use OEM-spec sensors to avoid compatibility issues.

Case Study: A UK-based logistics firm resolved limp mode issues in their 2014 XF105 fleet by sourcing NOx sensors from Volgen Power and updating ECU firmware, reducing downtime by 20%.

3. Payload and Weight Optimization

Concern: The XF105’s 7,700 kg kerb weight limits payload capacity compared to competitors like the MAN TGX (7,400 kg) or Scania R-Series (7,500 kg). Technical Solution:

- Configuration: Choose the Space Cab (1,885 mm height, 2,490 mm width) over the Super Space Cab to save 154 lbs. Reduce fuel tank size (850L vs. 1,200L) for an additional 100 kg savings.

- Component Upgrades: Volgen Power’s remanufactured cylinder heads are 5 kg lighter than OEM units while maintaining structural integrity (yield strength: 350 MPa).

- Load Management: Use DAF’s Fleet Management System to optimize load distribution, increasing payload efficiency by up to 5%.

4. High Maintenance Costs

Concern: Cylinder head repairs or replacements can cost €2,000–€5,000, straining fleet budgets. Technical Solution:

- Predictive Maintenance: Monitor key parameters like oil pressure (4–6 bar at 2,000 RPM) and injector pulse width (1.2–1.8 ms) using DAF’s diagnostics. Check valve clearances (intake: 0.40 mm, exhaust: 0.60 mm) every 120,000 km.

- Cost-Effective Parts: Volgen Power’s remanufactured cylinder heads start at €1,200, offering 30–40% savings compared to OEM units. Their global supply chain ensures delivery within 3–7 days.

- Warranty: Volgen Power provides a 12-month warranty on remanufactured parts, reducing financial risk.

Case Study: A Dutch transport company with 20 XF105 trucks saved €25,000 annually by sourcing remanufactured heads from Volgen Power and implementing predictive maintenance via DAVIE diagnostics.

Installation and Maintenance Best Practices

Proper installation and maintenance of the XF105 cylinder head are critical to its longevity and performance. Below are detailed steps and tips:

Installation Process

- Preparation: Drain coolant and remove ancillaries (turbocharger, injectors, camshaft). Clean mating surfaces to <0.05 mm flatness using a precision straightedge.

- Inspection: Check liner protrusion (0.02–0.05 mm) and head bolt threads for wear. Replace bolts if elongation exceeds 0.1 mm.

- Assembly: Install a new gasket (Part No. 1699644) and torque head bolts to 300 Nm in a crisscross pattern (three stages: 100 Nm, 200 Nm, 300 Nm). Ensure valve timing aligns with TDC markings.

- Post-Installation: Pressure-test the cooling system (1.5 bar) and verify injector calibration (pulse width: 1.2–1.8 ms). Run the engine at idle for 10 minutes to check for leaks.

Pro Tip: Use a torque-angle gauge for precise bolt tightening to prevent head warping. Volgen Power’s installation guides, available with their cylinder head kits, provide step-by-step instructions.

Maintenance Schedule

- Every 80,000 km: Pressure-test cooling system and inspect coolant passages for scale buildup.

- Every 120,000 km: Check valve clearances and clean EGR/SCR systems.

- Every 150,000 km: Inspect cylinder head for micro-cracks and resurface if flatness exceeds 0.05 mm.

- Annually: Flush the coolant system with MB 236.1-compliant fluid and replace the thermostat if the opening temperature exceeds 85°C.

Tools Required: DAVIE diagnostic tool, magnaflux tester, torque-angle wrench, borescope.

Cost-Benefit Analysis: OEM vs. Remanufactured Cylinder Heads

Choosing between OEM and remanufactured cylinder heads involves balancing cost, reliability, and availability. Here’s a breakdown:

| Factor | OEM Cylinder Head | Volgen Power Remanufactured |

|---|---|---|

| Price | €3,000–€5,000 | €1,200–€2,500 |

| Weight | 85 kg | 80 kg (lightweight option) |

| Warranty | 12–24 months | 12 months |

| Availability | 7–14 days | 3–7 days (global shipping) |

| Testing | Factory standards | Pressure-tested (30 bar), flatness (<0.05 mm) |

| Emissions Compliance | Euro 5/6 | Euro 5/6 |

Verdict: Volgen Power’s remanufactured heads offer comparable performance at a lower cost, with faster delivery and rigorous testing. For budget-conscious fleets, they’re a smart choice without sacrificing reliability.

Environmental Impact and Sustainability

The XF105’s cylinder head plays a key role in meeting Euro 6 emissions standards, reducing NOx emissions by 80% and particulate matter by 50% compared to Euro 4 engines. Its integrated EGR and SCR systems optimize combustion efficiency, lowering CO2 output to ~900 g/km in real-world conditions. Choosing remanufactured heads from Volgen Power further reduces environmental impact by recycling components, cutting waste by 70% compared to new part production. For eco-conscious fleets, this aligns with global sustainability goals while maintaining performance.

Comparing the XF105 Cylinder Head to Competitors

How does the XF105’s cylinder head stack up against competitors like the MAN TGX and Scania R-Series?

- MAN TGX (D26 Engine): Uses a cast-iron cylinder head, heavier (95 kg) but slightly more durable under extreme loads. However, its two-valve-per-cylinder design limits airflow compared to the XF105’s four-valve setup, resulting in 5% lower fuel efficiency.

- Scania R-Series (DC13 Engine): Features a composite head with similar weight (83 kg) but requires more frequent valve adjustments (every 100,000 km). Its injector system (2,200 bar max) is less advanced than the XF105’s 2,500 bar setup.

- XF105 Advantage: Lightweight design, superior airflow, and integrated manifold make it ideal for fuel efficiency and long-haul reliability.

Data Point: In a 2023 fleet test by a German logistics company, XF105 trucks averaged 2.9 km/liter, outperforming the MAN TGX (2.7 km/liter) and Scania R-Series (2.8 km/liter) under identical conditions.

Why Volgen Power is Your Trusted Supplier

Volgen Power is a leading supplier of DAF XF105 engine components, offering a comprehensive range of cylinder heads, gaskets, and full engine assemblies. Their key advantages include:

- Inventory: New, used, and remanufactured heads for MX300–MX410 engines (e.g., Part No. 0683657, 1699644 gasket kit).

- Quality Control: Parts undergo pressure testing (30 bar), surface planing (<0.05 mm flatness), and valve seat integrity checks.

- Global Logistics: Delivery to over 50 countries within 3–7 days, with expedited options for urgent needs.

- Technical Support: Access to DAF service manuals, installation guides, and remote diagnostics for ECU and sensor issues.

- Pricing: Remanufactured heads start at €1,200, with bulk discounts for fleets.

Shop Now: Explore Volgen Power’s DAF XF105 Parts or contact their team for custom quotes and technical assistance.

Expert Tips for Optimal Cylinder Head Performance

FAQs.

Q: What are the signs of a failing cylinder head?

A: Coolant loss, overheating (>95°C), white exhaust smoke, or fault codes (e.g., P0300). Perform a compression test (28–32 bar) to confirm.

Q: How often should I inspect the cylinder head?

A: Every 100,000–150,000 km or during major overhauls. See DAF’s maintenance schedule.

Q: Are remanufactured cylinder heads reliable?

A: Yes, Volgen Power’s heads are tested for pressure (30 bar) and flatness (<0.05 mm), matching OEM performance.

Q: Why does my XF105 enter limp mode?

A: Common causes include NOx sensor faults (P0401) or EGR valve issues. Volgen Power’s diagnostic support can resolve these quickly.

Q: Where can I source XF105 parts?

A: Volgen Power offers a full range with global shipping and technical support.

Related Articles for Further Reading

- Cylinder Head Design Innovations – Technical insights into modern engine heads

- DAF XF105 Technical Specs – Detailed model overview

- Diagnosing Truck Engine Faults – Practical troubleshooting guide

- PACCAR MX Engine Care – Maintenance best practices

- Truck Emissions and Euro 6 Compliance – Impact of modern engine designs

Power Your XF105 with Volgen Power

Maximize your DAF XF105’s performance with Volgen Power’s high-quality cylinder heads, gaskets, and engine components. Their remanufactured parts offer OEM-level reliability at a fraction of the cost, backed by global shipping and expert support. Visit Volgen Power to browse their inventory or request a quote for your fleet’s needs. For more on the XF105, explore DAF’s official XF range. Keep your trucks running efficiently—act now!