If you’re a truck driver or fleet manager in Toronto, Vancouver, or anywhere across Canada, your Cummins X15 engine is likely the backbone of your heavy-duty truck. But when the air compressor stops building pressure, it can spell trouble—slow brakes, warning buzzers, or even a car that won’t move. Low air pressure in your Cummins X15 air compressor can disrupt critical systems, such as air brakes and suspension, especially in harsh Canadian winters. This guide dives into the top five reasons your compressor isn’t working and offers simple, step-by-step fixes for truck air compressor repair. Whether you’re troubleshooting in a Toronto truck maintenance shop or a Vancouver heavy-duty repair garage, we’ve got practical solutions, real-world examples, and quality parts from Volgen Power to keep you rolling.

Table of Contents

1. Stuck or Faulty Unloader Valve

Why It Happens: The unloader valve controls when your compressor builds pressure or idles. Carbon buildup from the exhaust gas recirculation (EGR) system—common in Cummins X15 engines, especially 2008-2010 models—can make it stick, stopping pressure buildup. This is a frequent issue in Toronto truck maintenance shops where EGR residue accumulates faster in cold weather.

Signs of Trouble:

- Air pressure lingers below 90 PSI at idle.

- Tapping the compressor head temporarily boosts pressure.

- Compressor cycles but doesn’t reach 120 PSI.

How to Fix It:

- Drain the Air Tanks: Release all air pressure to zero for safety.

- Clean the Valve: Disconnect the governor line and spray WD-40 into the unloader valve to dissolve carbon.

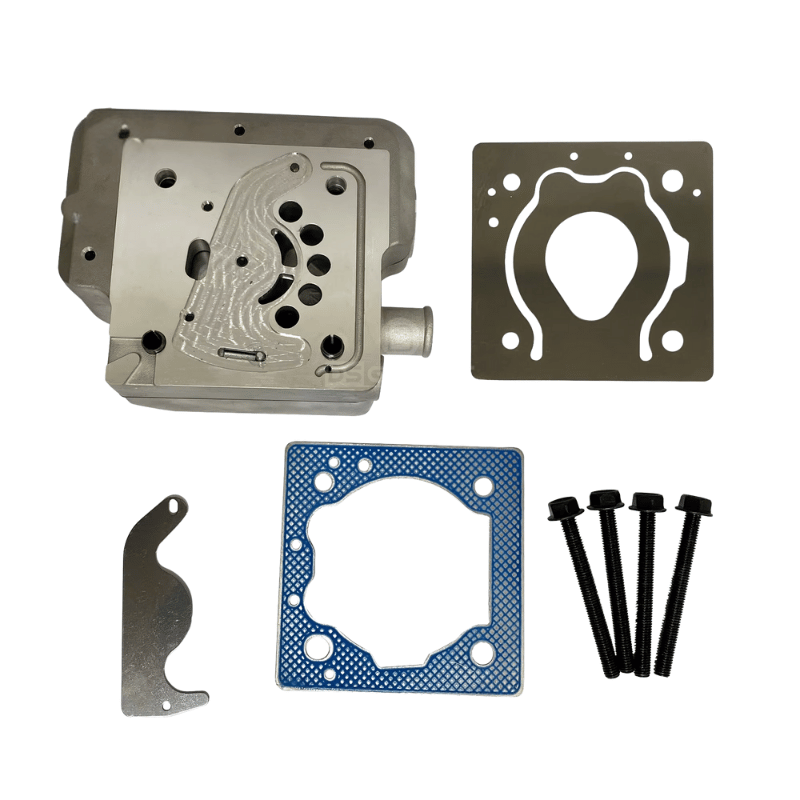

- Replace if Needed: If cleaning fails, install a Cummins X15 unloader valve kit from Volgen Power.

- Test the System: Run the engine at 1000-1500 RPM to ensure pressure hits 120 PSI within 45 seconds.

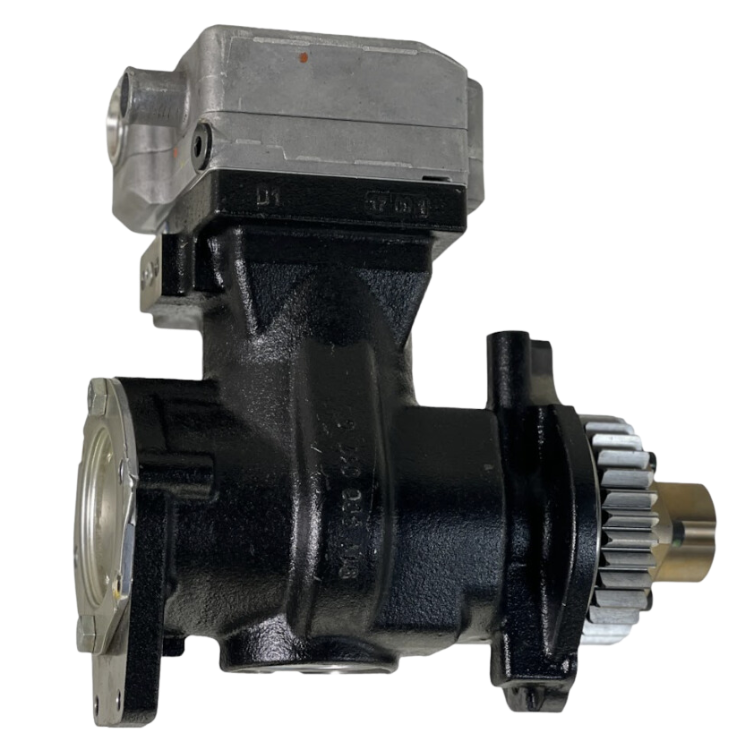

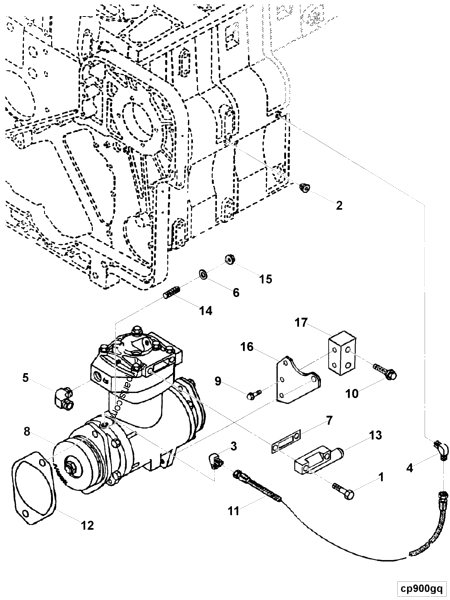

Visual Aid: See the Cummins X15 air compressor diagram to locate the unloader valve on your engine.

Real-World Example: Jake, a driver in Toronto, noticed his X15’s pressure stuck at 85 PSI during a winter haul. Cleaning the unloader valve saved him a trip to the shop, a common fix in Toronto truck maintenance routines.

Driver Tip: Check the unloader valve every 6 months, especially in Vancouver’s damp climate, to prevent carbon buildup.

2. Air Leaks in the Pneumatic System

Why It Happens: Leaks in air lines, fittings, or the discharge line can rob your compressor of pressure. This is a common issue in Vancouver heavy-duty truck repair shops, where road salt and moisture can corrode lines.

Signs of Trouble:

- Hissing sounds near air lines or fittings.

- Pressure builds slowly or drops after hitting 100 PSI.

- Uneven pressure in primary and secondary tanks.

How to Fix It:

- Locate the Leak: Spray soapy water on air lines and fittings to spot bubbles.

- Replace Damaged Parts: Swap out cracked lines with durable air lines from Volgen Power.

- Check the Discharge Line: Ensure the braided line to the air dryer isn’t too long or heat-damaged, per Cummins OEM specs.

Real-World Example: Emma, a fleet manager in Vancouver, found a hissing fitting during a routine check. Replacing it with a Volgen Power part restored pressure in under an hour.

Driver Tip: Add leak checks to your daily pre-trip inspections, especially in Toronto and Vancouver, where winter road conditions can accelerate wear.

3. Clogged Air Intake Filter

Why It Happens: A dirty air intake filter restricts airflow, forcing the compressor to work harder and build pressure slowly. This is common in dusty construction zones around Toronto and Vancouver.

Signs of Trouble:

- Pressure takes over a minute to reach 120 PSI.

- Oil in the air lines or air dryer, indicating overworking.

- The compressor runs hotter than normal.

How to Fix It:

- Inspect the Filter: Remove the air intake filter and check for dirt or debris.

- Clean or Replace: Clean reusable filters or replace them with OEM-quality air filters from Volgen Power.

- Run a Pump-Up Test: Confirm pressure builds to 120 PSI within 45 seconds.

Visual Aid: Check the Cummins X15 air compressor diagram to locate the intake filter.

Real-World Example: Raj, a driver in Toronto, fixed slow pressure buildup by replacing a clogged filter, a quick win for his Toronto truck maintenance routine.

Driver Tip: Replace filters every 3-6 months, especially in Vancouver’s dusty or coastal environments.

4. Worn Piston Rings or Cylinder Walls

Why It Happens: High-mileage X15 engines or those with skipped maintenance can develop worn piston rings or cylinder walls, reducing compression efficiency. This is a frequent issue in Vancouver heavy-duty truck repair shops handling older fleets.

Signs of Trouble:

- Pressure struggles to build, even at 1500+ RPM.

- Oil blow-by in the air system.

- Grinding or knocking noises from the compressor.

How to Fix It:

- Test Compression: Use a compression tester to check the output.

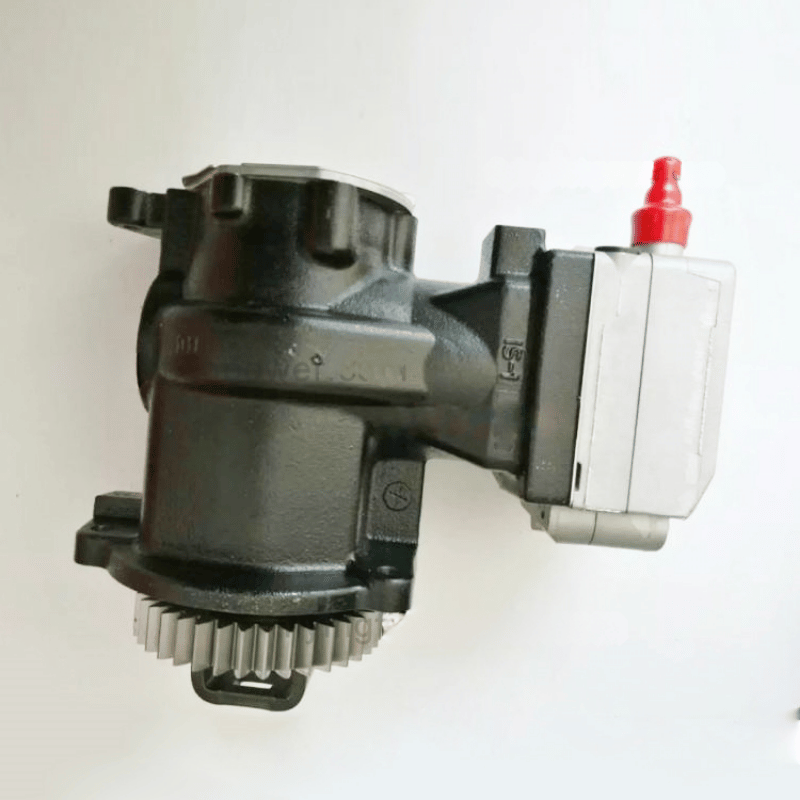

- Replace the Compressor: If worn, install a remanufactured Cummins X15 air compressor from Volgen Power.

- Inspect Related Parts: Check cylinder head valves and gaskets for wear.

Real-World Example: Sam, a sprung> fleet owner in Manitoba, replaced his 600,000-mile X15’s compressor with a Volgen Power unit, saving thousands over a shop rebuild.

Driver Tip: Regular oil changes (every 10,000-15,000 miles) prevent premature wear, a must for Toronto and Vancouver’s demanding routes.

5. Faulty Air Governor

Why It Happens: The air governor controls compressor cycling. A faulty governor can prevent engagement or cause overworking, disrupting pressure in your diesel engine air system.

Signs of Trouble:

- The compressor doesn’t cycle on at 80 PSI or off at 120-135 PSI.

- Pressure stays low or spikes too high.

- Air gauges show no change.

How to Fix It:

- Test the Governor: Pump the system to 80 PSI and verify compressor engagement, then check unloading at 120-135 PSI.

- Replace if Faulty: Install a Cummins-compatible air governor from Volgen Power.

- Check Sensing Lines: Ensure lines are free of leaks or clogs.

Real-World Example: Maria, a driver in Vancouver, fixed erratic cycling with a new Volgen Power governor, a quick fix for her winter haul.

Driver Tip: Test the governor annually to avoid pressure issues, especially in Toronto’s stop-and-go traffic.

Winter Maintenance for Cummins X15 Air Compressors in Canada

Canada’s brutal winters—especially in Toronto and Vancouver—can wreak havoc on your Cummins X15 air compressor. Cold thickens oil, accelerates EGR carbon buildup, and freezes air lines, leading to low pressure. Here’s how to keep your compressor ready for Toronto truck maintenance and Vancouver heavy-duty truck repair challenges:

- Prevent Air Line Freezing: Use alcohol-based air dryer additives to remove moisture, preventing frozen lines. Find air dryer solutions at Volgen Power.

- Combat Carbon Buildup: Cold weather worsens EGR residue in the unloader valve. Clean every 3 months or use a Volgen Power unloader valve kit.

- Insulate Air Lines: Protect lines from Toronto’s salt or Vancouver’s dampness with insulation or Volgen Power air line kits.

- Warm Up Properly: Idle the engine for 5-10 minutes to warm the compressor, crucial in -30°C Winnipeg winters.

- Maintain the Air Dryer: Replace air dryer cartridges regularly to avoid moisture buildup, available at Volgen Power.

Real-World Example: In Toronto, driver Ahmed used an air dryer additive and insulated lines to keep his X15’s air system running through a February snowstorm.

Driver Tip: Stock up on additives before winter hits Toronto or Vancouver to avoid emergency repairs.

Preventive Maintenance to Avoid Compressor Issues

To keep your Cummins X15 air compressor humming in Toronto and Vancouver:

- Daily Checks: Listen for hissing, check gauges, and inspect for oil in the air system.

- Quality Parts: Use OEM or Volgen Power parts for durability.

- Maintenance Schedule: Replace filters every 3-6 months, clean unloader valves biannually, and test governors yearly.

- Monitor Conditions: Avoid continuous compressor use to prevent overheating.

- Professional Help: For complex issues, visit a certified Cummins shop in Toronto or Vancouver.

Driver Tip: Keep a toolkit with WD-40, a compression tester, and spare fittings for quick fixes on the road.

Related Reading

FAQs.

Q: How fast should my Cummins X15 air compressor build pressure?

A: From 0 to 120 PSI in 45 seconds at 1000-1500 RPM. If slower, check for leaks or clogged filters.

Q: What are the signs of a failing Cummins X15 air compressor?

A: Slow pressure buildup, oil in air lines, grinding noises, or overheating.

Q: Can I clean a stuck unloader valve myself?

A: Yes, use WD-40 to dissolve carbon buildup. If unsuccessful, get a Volgen Power unloader valve kit.

Q: How often should I replace my compressor’s air filter?

A: Every 3-6 months, or more in Toronto’s dusty construction zones or Vancouver’s coastal air.

Q: What if my compressor doesn’t build pressure after troubleshooting?

A: It may need replacement. Try a Volgen Power remanufactured compressor.

Q: Are aftermarket parts safe for Cummins X15 compressors?

A: High-quality parts from Volgen Power meet or exceed OEM standards. Verify compatibility.

Q: How do I prevent compressor issues in Toronto and Vancouver winters?

A: Use air dryer additives, insulate lines, and clean unloader valves regularly.

Q: Why is my compressor noisy but not building pressure?

A: Likely worn piston rings, a stuck unloader valve, or leaks.

Q: Where can I find a Cummins X15 repair shop in Toronto or Vancouver?

A: Check Volgen Power’s service directory for certified shops.

Conclusion

A Cummins X15 air compressor not building pressure can disrupt your hauls, especially in the demanding conditions of Toronto truck maintenance or Vancouver heavy-duty truck repair. From stuck unloader valves to air leaks, clogged filters, worn piston rings, or faulty governors, this guide provides clear fixes backed by video tutorials and diagrams. Canadian drivers, take extra care in winter with our tailored maintenance tips. By using Volgen Power’s quality parts and sticking to a solid maintenance plan, you’ll keep your truck’s air system reliable.

Visit Volgen Power’s catalog for top-tier Cummins X15 parts and keep your fleet rolling strong in Toronto, Vancouver, and beyond.