Cummins M11 ECM plays a vital role in engine performance, controlling fuel injection and throttle response. Failure can lead to downtime and power loss. Volgen Power’s guide examines repair versus replacement, providing diagnostics and expert solutions for reliability. Trust our services for informed decisions.

Table of Contents

Understanding the Cummins M11 ECM and Its Role

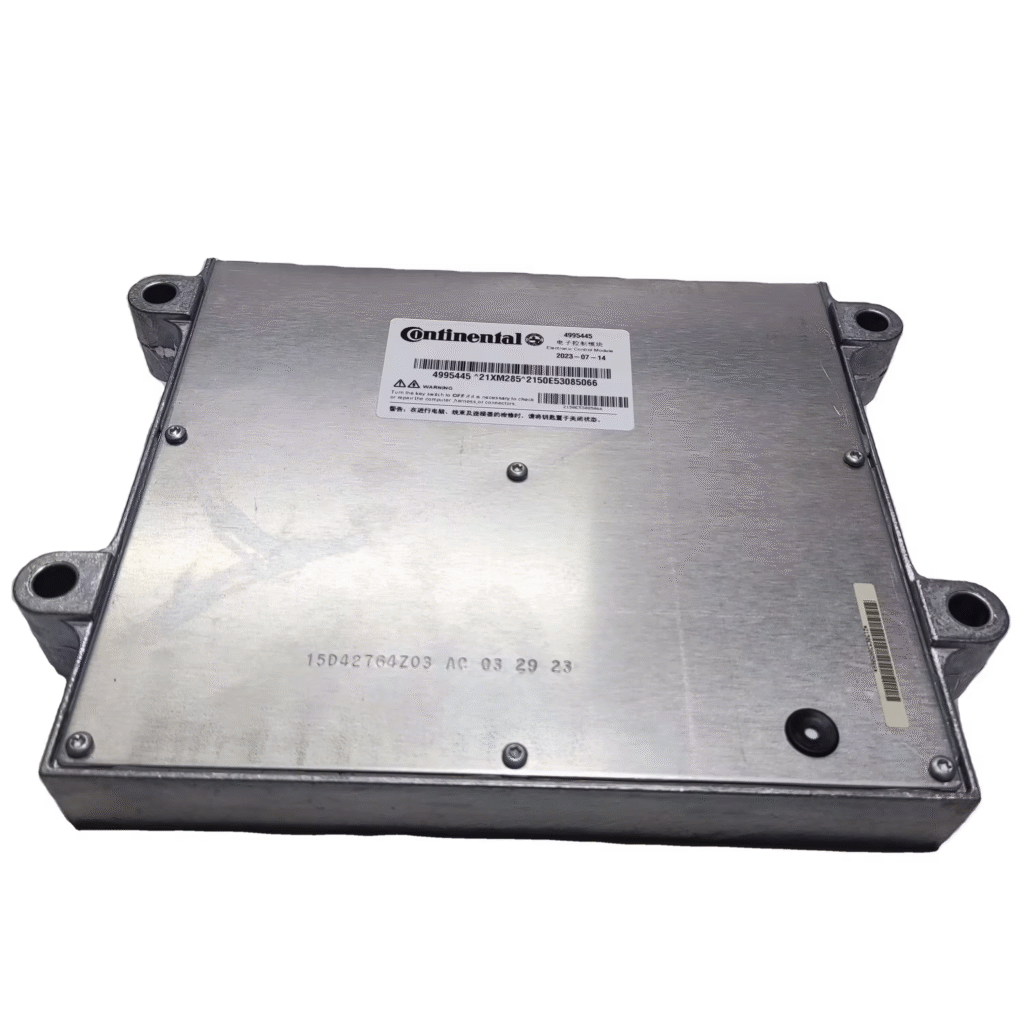

The Cummins M11, a robust 11-liter diesel engine, powers heavy-duty trucks, construction equipment, and industrial applications with horsepower ratings typically ranging from 370 to 450 hp. The ECM (part number 4963807) acts as the engine’s brain, processing data from sensors like the throttle position sensor, coolant temperature sensor, and crankshaft position sensor to optimize performance and ensure compliance with emissions standards.

Key Functions of the M11 ECM

- Fuel Management: Regulates fuel injector timing and volume for efficiency and power.

- Throttle Control: Interprets signals from the throttle position sensor for smooth acceleration.

- Emissions Compliance: Adjusts engine parameters to meet EPA standards.

- Diagnostics: Stores fault codes to identify issues like misfires or sensor failures.

- Turbo Boost: Manages turbocharger performance for optimal power output.

When the ECM malfunctions, symptoms like rough idling, reduced power, or fault codes (e.g., injector circuit errors) can disrupt operations. According to diesel technician John Carter from Midwest ECM Repair, “A failing ECM can mimic other engine problems, so accurate diagnostics are critical before deciding on repair or replacement.” Source

Signs Your Cummins M11 ECM Needs Attention

Before deciding whether to repair or replace your M11 ECM, you need to identify the symptoms of failure. Common indicators include:

- Fault Codes: Persistent diagnostic trouble codes (DTCs) such as SPN 111 (coolant level sensor) or SPN 629 (ECM internal error).

- Performance Issues: Loss of power, erratic throttle response, or poor fuel economy.

- Starting Problems: Difficulty starting the engine or frequent stalling.

- Overheating: The ECM overheats due to a faulty cooling plate or poor ventilation.

- Wiring Issues: Corroded or damaged wiring harness connectors are causing communication failures.

To confirm ECM issues, use a diagnostic tool like Cummins INSITE to read fault codes and test sensor inputs. For detailed troubleshooting steps, check our Cummins M11 ECM Problems Guide.

Repair vs. Replacement: Key Factors to Consider

Deciding whether to repair or replace your Cummins M11 ECM (part number 4963807) depends on several factors, including cost, downtime, the extent of damage, and long-term reliability. Below, we break down each consideration to help you make an informed decision.

1. Extent of ECM Damage

The severity of the ECM’s issues is the primary factor in choosing repair or replacement.

When to Repair

- Minor Electrical Issues: Faulty capacitors, resistors, or solder joints can often be fixed by skilled technicians.

- Software Corruption: Corrupted firmware or calibration data can be reprogrammed using tools like Cummins INSITE.

- Connector Problems: Corroded or loose pins in the ECM connector can be cleaned or replaced.

- Intermittent Fault Codes: Temporary glitches caused by voltage spikes or sensor misreads can be resolved with a reset or recalibration.

Expert Insight: “Many ECM failures are due to fixable issues like burnt circuits or bad connectors. Repairing saves money if the core module is intact,” says Sarah Lopez, lead technician at SIA Electronics. Source

When to Replace

- Physical Damage: Cracked casings, burnt circuit boards, or severe overheating (e.g., melted cooling plate) render the ECM unrepairable.

- EEPROM Failure: Permanent corruption of the ECM’s memory chip (EEPROM) requires a new module.

- Recurring Failures: If repairs fail to resolve issues after multiple attempts, replacement is more reliable.

- Obsolete Hardware: Older M11 ECMs may lack compatibility with modern diagnostic tools or emissions standards.

2. Cost Considerations

Cost is a major factor for truck owners and fleet managers. Here’s a breakdown:

Repair Costs

Typical Range: $300–$800, depending on the issue (e.g., circuit board repair vs. reprogramming).

Advantages: Repairs are often 50–70% cheaper than replacements, preserving the original ECM’s calibration data.

Drawbacks: Repairs may not address underlying issues like aging hardware, leading to future failures.

Replacement Costs

- OEM ECM: $1,500–$3,000 for a new M11 ECM (part number 4963807), plus labor for installation and programming.

- Aftermarket ECM: $800–$1,500, but quality varies, and compatibility issues may arise.

- Advantages: New ECMs offer updated firmware and longer lifespans.

- Drawbacks: Higher upfront costs and potential delays in sourcing parts.

Volgen Power offers competitive pricing on both repairs and replacements, with free diagnostic quotes to help you decide. Request a Quote Today.

3. Downtime and Availability

Downtime is a critical concern for fleets and owner-operators.

Repair: Typically takes 2–5 days, depending on the repair shop’s workload and parts availability. Volgen Power’s streamlined process ensures fast turnaround, often within 48 hours.

Replacement: May take longer (5–10 days) if sourcing a new ECM, especially for less common models. Aftermarket ECMs are more readily available but require careful vetting for quality.

4. Long-Term Reliability

Repaired ECMs: Can last years if the repair addresses the root cause (e.g., fixing a faulty power supply). However, aging components may lead to future issues.

New ECMs: Offer greater reliability and come with warranties (typically 1–2 years), but improper installation or calibration can negate these benefits.

5. Warranty and Support

- Repairs: Volgen Power provides a 6-month warranty on ECM repairs, covering parts and labor.

- Replacements: New OEM ECMs come with Cummins’ 1-year warranty, while aftermarket units vary (check supplier terms).

- Professional Installation: Proper programming and calibration are crucial to avoid warranty voids. Learn more in our Cummins ECM Calibration Guide.

Step-by-Step Process for Diagnosing M11 ECM Issues

Before committing to repair or replacement, accurate diagnostics are essential to identify the root cause of ECM problems. Follow these steps:

Step 1: Read Fault Codes

Connect a diagnostic tool like Cummins INSITE to the truck’s OBD-II port.

Record active and inactive fault codes (e.g., SPN 629 for ECM internal errors).

Cross-reference codes with the Cummins M11 service manual or our Cummins M11 ECM Troubleshooting Guide.

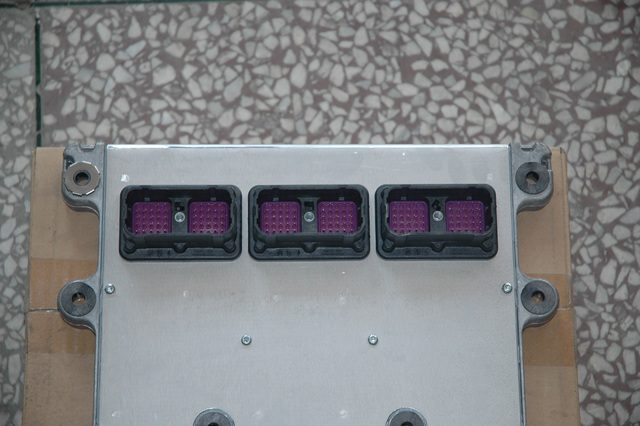

Step 2: Inspect the ECM and Wiring

Physical Inspection: Check the ECM (part number 4963807) for cracks, burns, or coolant leaks. Inspect the cooling plate for damage, as overheating is a common issue.

Wiring Harness: Examine the ECM connector and wiring harness for corrosion, loose pins, or frayed wires. Refer to our Cummins M11 ECM Wiring Diagram PDF.

Power Supply: Use a multimeter to verify the ECM receives 12–14 volts. Check the ECM fuse location (typically near the battery or fuse box) for blown fuses.

Step 3: Test Related Components

Throttle Position Sensor: Faulty sensors can mimic ECM issues. Test with a multimeter for consistent voltage output.

Fuel Solenoids: A failing solenoid can overload the ECM, causing fault codes.

Sensors: Check coolant, crankshaft, and camshaft sensors for proper operation.

Step 4: Attempt a Soft Reset

Disconnect the battery (negative first, then positive) for 15–20 minutes to clear volatile memory.

Reconnect and test the engine. If issues persist, proceed to professional diagnostics.

Step 5: Consult a Professional

If diagnostics reveal complex issues (e.g., EEPROM corruption or burnt circuits), contact Volgen Power for expert analysis. Our technicians use advanced tools to determine whether repair or replacement is the best solution.

Repairing Your Cummins M11 ECM: What to Expect

Repairing an M11 ECM is often the preferred choice for cost-conscious owners, provided the module is salvageable. Here’s what the process entails:

Common Repair Scenarios

- Circuit Board Fixes: Replacing damaged capacitors, resistors, or solder joints.

- Connector Repairs: Cleaning or replacing corroded pins in the ECM connector.

- Firmware Reprogramming: Restoring corrupted software or updating calibration data.

- Cooling Plate Maintenance: Replacing or upgrading the ECM cooling plate to prevent overheating.

Repair Process at Volgen Power

- Diagnostic Testing: We use Cummins INSITE and multimeters to pinpoint issues.

- Component-Level Repair: Our technicians repair circuit boards or replace faulty components.

- Reprogramming: We restore factory settings or update firmware to match your engine’s specifications.

- Testing: The repaired ECM is tested under real-world conditions to ensure reliability.

- Warranty: All repairs come with a 6-month warranty for peace of mind.

Benefits of Repair

Cost Savings: Repairs are significantly cheaper than replacements.

Preserves Calibration: Retains your engine’s original settings, avoiding reprogramming costs.

Eco-Friendly: Reduces electronic waste compared to replacing the module.

Limitations

Aging Hardware: Older ECMs may fail again due to wear and tear.

Complex Issues: Severe damage (e.g., burnt circuit boards) may make repair impossible.

Expert Insight: “Repairing an ECM is like fixing a computer—most issues are fixable if the core is intact, but a total meltdown means replacement,” says Tom Harris, diesel technician at Truck ECM Parts. Source

Replacing Your Cummins M11 ECM: What to Know

When repair isn’t viable, replacing the M11 ECM is the best option for long-term reliability. Here’s a detailed look at the replacement process:

Types of Replacement ECMs

OEM ECMs: Genuine Cummins M11 ECMs (part number 4963807) ensure compatibility and come with a 1-year warranty. Expect higher costs but superior quality.

Aftermarket ECMs: More affordable but vary in quality. Verify compatibility with your M11 engine to avoid issues.

Refurbished ECMs: Previously repaired units offered at a discount. Volgen Power thoroughly tests refurbished ECMs for reliability.

Replacement Process

- Sourcing the ECM: Volgen Power stocks OEM and high-quality aftermarket M11 ECMs for quick delivery.

- Installation: The new ECM is mounted in place of the old unit, ensuring proper connection to the wiring harness.

- Programming: The ECM is programmed with your engine’s specific calibration data using Cummins INSITE.

- Testing: The engine is tested for performance, fault codes, and emissions compliance.

- Warranty Activation: OEM ECMs include a Cummins warranty, while Volgen Power provides a warranty on aftermarket and refurbished units.

Benefits of Replacement

Reliability: New ECMs offer updated hardware and firmware for improved performance.

Longevity: A new module can last 5–10 years with proper maintenance.

Warranty: OEM units come with robust warranties, reducing future repair costs.

Limitations

Higher Costs: OEM ECMs are expensive, and programming adds to the total.

Availability: Rare models may have longer lead times for sourcing.

Programming Complexity: Incorrect calibration can cause performance issues or emissions violations.

Volgen Power simplifies the replacement process with in-stock M11 ECMs and expert programming services. Shop M11 ECMs Now.

How Volgen Power Can Help

At Volgen Power, we specialize in Cummins M11 ECM diagnostics, repairs, and replacements, offering tailored solutions for truck owners, fleet managers, and mechanics. Our services include:

- Free Diagnostics: Identify the root cause of ECM issues with no upfront cost.

- Expert Repairs: Fix circuit boards, connectors, and software issues with a 6-month warranty.

- OEM and Aftermarket ECMs: Source reliable M11 ECMs (part number 4963807) for quick replacements.

- Fast Turnaround: Minimize downtime with our streamlined repair and replacement process.

- Technical Support: Access free resources like our Cummins M11 ECM Wiring Diagram PDF.

FAQs.

Q: How do I know if my M11 ECM needs repair or replacement?

A: Diagnostics using Cummins INSITE can reveal whether issues are fixable (e.g., faulty circuits) or require replacement (e.g., burnt boards). Request a free diagnostic from Volgen Power at Contact Us (#contact-form).

Q: What causes M11 ECM failures?

A: Common causes include overheating, faulty fuel solenoids, wiring harness issues, or software corruption. Learn more in our What Causes Cummins ECM to Go Bad?.

Q: How much does an M11 ECM repair cost?

A: Repairs typically range from $300–$800, depending on the issue. Contact Volgen Power for a free quote tailored to your needs.

Q: Are aftermarket M11 ECMs reliable?

A: High-quality aftermarket ECMs can be reliable but require careful vetting. Volgen Power ensures compatibility and provides warranties on all units.

Q: How long does an ECM replacement take?

A: Replacement typically takes 5–10 days, including sourcing and programming. Volgen Power offers expedited services to reduce downtime.

Q: Can I install a new ECM myself?

A: Installation is possible with technical expertise, but programming requires Cummins INSITE. Avoid risks by using Volgen Power’s professional services.

Take Action to Restore Your Cummins M11 Engine

Deciding whether to repair or replace your Cummins M11 ECM (part number 4963807) is a critical choice that impacts your truck’s performance and your bottom line. By following our diagnostic steps and weighing factors like cost, downtime, and reliability, you can make an informed decision. Volgen Power is here to simplify the process with expert diagnostics, affordable repairs, and reliable ECM replacements. Don’t let ECM issues keep your truck off the road—reach out to our team today.