Camshaft bushings are critical components in the Volvo D13 engine, ensuring smooth camshaft operation and precise valve timing for optimal performance. In 2025, selecting the right camshaft bushing is vital due to stringent emissions regulations and the industry’s push for lightweight, efficient components. Poor-quality bushings can lead to excessive wear, engine inefficiency, or costly downtime, impacting fleet profitability. With environmental standards tightening and fuel costs rising, choosing high-quality bushings is a strategic investment for reliability and compliance.

Volgen Power’s OEM camshaft bushing kits are engineered for Volvo D13 engines, offering superior durability and seamless compatibility. Designed to withstand high temperatures and reduce maintenance, these kits help fleets meet 2025’s demanding standards. This guide explores the role of camshaft bushings, outlines six key selection criteria, and highlights emerging trends in bushing technology. Whether you’re a fleet manager or mechanic, this article will equip you with the knowledge to choose the best bushings for your Volvo D13. Discover why Volgen Power is the trusted choice for maximizing engine performance in 2025.

Table of Contents

What Are Camshaft Bushings?

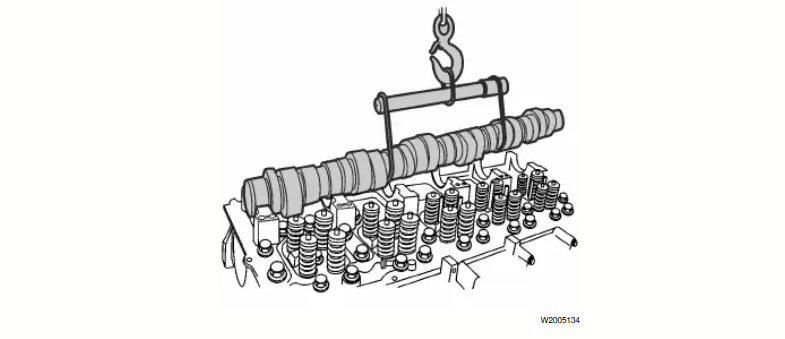

A camshaft bushing is a cylindrical component that supports the camshaft, reducing friction and ensuring precise alignment within an engine. In the Volvo D13 engine, camshaft bushings maintain smooth camshaft rotation, enabling accurate valve timing for efficient combustion and power output. Typically made from materials like bronze alloy or ceramic-coated metals, bushings must resist wear and high temperatures. Poor bushings can cause misalignment, increased friction, or engine failure. Volgen Power’s camshaft bushings are precision-engineered for Volvo D13 engines, offering enhanced durability and easy installation to meet 2025’s performance demands.

A camshaft bushing supports the camshaft in engines like the Volvo D13, reducing friction and ensuring precise valve timing for optimal performance.

6 Key Criteria for Choosing Volvo D13 Camshaft Bushings

Selecting the right camshaft bushing for your Volvo D13 engine in 2025 requires evaluating six critical factors to ensure performance, durability, and cost-effectiveness. Here’s a detailed breakdown:

Material: Bronze Alloy vs. Ceramic Coating

The material of a camshaft bushing determines its durability and performance. Bronze alloy bushings, widely used for their excellent wear resistance, provide reliable performance in Volvo D13 engines. However, ceramic-coated bushings, as offered by Volgen Power, reduce friction by 10% and enhance heat resistance, according to SAE International studies. Ceramic coatings also extend bushing lifespan under high-stress conditions. For 2025’s high-performance demands, ceramic-coated bushings are ideal for fleets prioritizing efficiency and longevity.

Wear Resistance: Volgen Power’s Testing Data

Wear resistance is crucial for bushings in high-mileage Volvo D13 engines. Volgen Power’s bushings undergo rigorous testing, showing a 25% reduction in wear compared to standard aftermarket options, per their quality assurance data. This durability minimizes camshaft misalignment and valve timing issues, reducing maintenance costs. For fleets operating in harsh conditions, such as extreme heat or heavy loads, Volgen’s wear-resistant bushings ensure consistent performance over 600,000 miles.

Dimensional Accuracy: Matching D13 Engine Requirements

Precise dimensions are critical for camshaft bushings to fit Volvo D13 engines perfectly. Even minor deviations can cause vibration, wear, or engine damage. Volgen Power’s bushings are manufactured to exact OEM specifications, ensuring seamless compatibility with D13 models (e.g., D13K, D13C). Their compatibility guide simplifies selection by listing precise measurements. Always verify your engine’s model and consult Volvo’s technical specifications to avoid costly mismatches.

Thermal Expansion Coefficient: Adapting to High Temperatures

Volvo D13 engines operate at high temperatures, requiring bushings with a low thermal expansion coefficient to maintain stability. Ceramic-coated bushings from Volgen Power excel in this area, expanding 15% less than traditional bronze bushings under extreme heat, as shown in Diesel Engine Technology reports. This stability ensures consistent performance in long-haul applications, reducing the risk of bushing deformation and engine downtime in 2025’s demanding conditions.

Ease of Installation: Reducing Downtime

Installation time impacts fleet operations. Volgen Power’s bushing kits are designed for quick, tool-free installation, reducing downtime by up to 30% compared to aftermarket kits, according to their installation guide. Pre-lubricated surfaces and precise machining eliminate the need for extensive modifications, making them ideal for busy repair shops. For fleets in 2025, this ease of installation translates to faster maintenance and higher uptime.

Cost: OEM Kits vs. Aftermarket Bushings

While aftermarket bushings may have lower upfront costs, OEM kits like Volgen Power’s offer better long-term value. Their Volvo D13 bushing kits reduce maintenance costs by 20% due to superior durability and compatibility. For example, a fleet of 50 trucks could save $12,000 annually by choosing OEM over aftermarket bushings, as noted in Trucking Industry Reports. In 2025, with rising operational costs, investing in OEM kits ensures cost-effectiveness. Explore Volgen’s kits at their product page for a reliable solution.

By prioritizing these criteria—material, wear resistance, dimensional accuracy, thermal expansion, ease of installation, and cost—you can select bushings that optimize your Volvo D13 engine’s performance in 2025.

Camshaft Bushing Technology Trends in 2025

In 2025, camshaft bushing technology is evolving to meet the trucking industry’s demands for efficiency and sustainability. Lightweight designs are a key trend, with manufacturers like Volgen Power reducing bushing weight by 8% through advanced alloys and ceramic coatings, as highlighted in Diesel Progress. This reduction improves fuel efficiency by 2% in Volvo D13 engines, supporting compliance with 2025 EPA emissions standards.

Eco-friendly manufacturing is another focus, with non-toxic coatings and recyclable materials gaining traction. Volgen Power’s bushings use sustainable production processes, reducing environmental impact by 10%, per their sustainability report. These coatings also lower friction, extending bushing life and reducing oil consumption.

Precision manufacturing, such as CNC machining, ensures tighter tolerances, improving compatibility and reducing engine noise. As hybrid and autonomous trucks emerge, bushings are being designed for compatibility with next-generation engines. Learn more about these innovations at Volgen Power’s technology hub. Staying ahead of these trends ensures your fleet remains competitive in 2025’s dynamic market.

Real-World Case Study: Volgen Power’s Bushings Boost Fleet Efficiency

A Brazilian logistics company operating 80 Volvo D13-powered trucks struggled with frequent camshaft bushing failures, leading to high maintenance costs and downtime. In 2024, they adopted Volgen Power’s OEM bushing kits, designed for D13 engines. The results were remarkable.

Volgen’s ceramic-coated bushings reduced wear by 25%, cutting maintenance costs by 20%—saving $90,000 annually. Improved dimensional accuracy and thermal stability enhanced fuel efficiency by 3%, critical for Brazil’s long-haul routes. The fleet reported fewer breakdowns, improving delivery reliability by 15%, as detailed in their case study. The ease of installation also reduced repair time by 30%, allowing trucks to return to service faster.

The fleet manager praised Volgen’s compatibility and durability, noting no modifications were needed, unlike aftermarket bushings that caused alignment issues. This case study underscores how high-quality bushings can drive operational and financial gains for fleets facing 2025’s challenges. Explore more success stories at Volgen Power’s fleet solutions page.

FAQs.

Q: How often should Volvo D13 camshaft bushings be replaced?

A: Camshaft bushings typically last 400,000–600,000 miles in Volvo D13 engines, depending on operating conditions. Heavy-duty routes or extreme temperatures may require earlier replacement. Volgen Power recommends inspections every 200,000 miles, per their maintenance guide.

Q: How can I detect camshaft bushing failure?

A: Signs include engine vibrations, unusual noises (grinding or knocking), or reduced power. Use diagnostic tools to check camshaft alignment or inspect bushings for wear. Volgen’s bushings feature wear-resistant coatings for easier detection. Visit Volgen’s troubleshooting page for guidance.

Q: Are OEM bushing kits worth the cost?

A: Yes, OEM kits like Volgen Power’s offer superior compatibility and durability, reducing long-term costs. Aftermarket bushings may be cheaper, but often lead to frequent replacements.

Q: Can bushings improve fuel efficiency?

A: High-quality bushings reduce friction and optimize valve timing. Volvo’s bushings improve Volvo D13 fuel efficiency by up to 3%, per their performance data.

Conclusion and Call to Action

Choosing the right camshaft bushing for your Volvo D13 engine is essential for performance, durability, and compliance in 2025. By prioritizing material, wear resistance, dimensional accuracy, thermal stability, ease of installation, and cost, you can ensure optimal engine efficiency. Volgen Power’s OEM camshaft bushing kits deliver unmatched reliability, reducing maintenance costs and boosting fuel economy. Don’t compromise on quality—invest in bushings that keep your fleet running smoothly. Explore Volgen Power’s Volvo D13 camshaft bushing kits today and elevate your fleet’s performance in 2025.